We've got some exciting updates to share from the Envirocon team. This summer, we rolled up our sleeves and got to work on a major overhaul of our Penrose factory. The result? A revamped layout that's all about boosting efficiency, safety, and sustainability in the world of ready mix concrete.

Here's the lowdown: we've implemented a slick one-way traffic flow system within our factory grounds. This simple change might not sound like much, but it's making a world of difference. By minimising truck reversing and simplifying traffic flow, we're slashing turnaround times and keeping operations running smoothly. This has a big impact on our members who rely on fast efficient truck turn around times.

But that's not the only improvement we've made. We've also ramped up our factory's capacity, going from handling just two trucks at a time to up to five at a time! That means we can process more concrete, faster, and with fewer bottlenecks along the way.

Of course, safety is always top of mind for us. By eliminating truck reversing and improving visibility, we're reducing risks and creating a safer work environment for everyone involved. And by separating traffic within the factory, we're adding an extra layer of protection to ensure smooth operations.

But wait, there's more! We've got some other exciting projects in the pipeline too. Keep your eyes peeled for updates on two new locations opening soon, as well as some handy tools to help track zero waste in the construction industry.

About Envirocon:

Envirocon is a leader in sustainability, zero waste, and circular economy solutions. Envirocon is a Product Stewardship Scheme Accredited by the Minister for the Environment under the Waste Minimisation Act 2008, we're leading the charge in sustainable solutions for excess ready mix concrete.

From transforming excess concrete into reusable precast elements to diverting thousands of tons of waste from landfills, we're committed to making a positive impact on the environment - including reducing carbon emissions by an estimated 2.8mill kgCO2e over the next twelve months. With a dedicated team spread across the country, we're working tirelessly to build a greener, more sustainable future for the construction industry.

Join us on our journey towards a zero-waste tomorrow.

3 Concrete Mix Options Offer You More Choice

We're excited to announce the launch of Total Precast Solutions (TPS), an initiative that gives you the ability to minimise embodied carbon impact without comprimising the technical requirements. TPS offers three concrete mix options across all Envirocon product ranges, including Interbloc and Stonebloc.

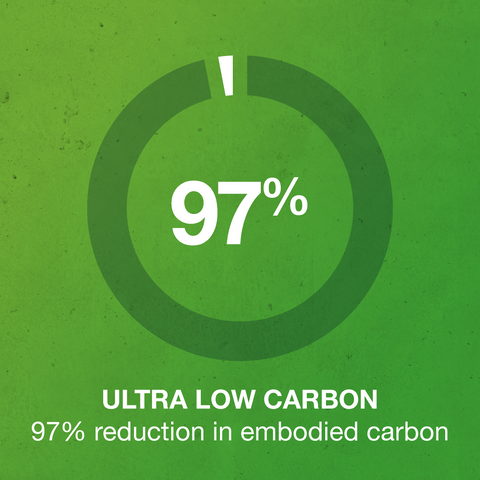

| Ultra Low Carbon: This is the standard choice, with an EPD-certified ~ 97% reduction in embodied carbon compared to standard concrete mixes. |

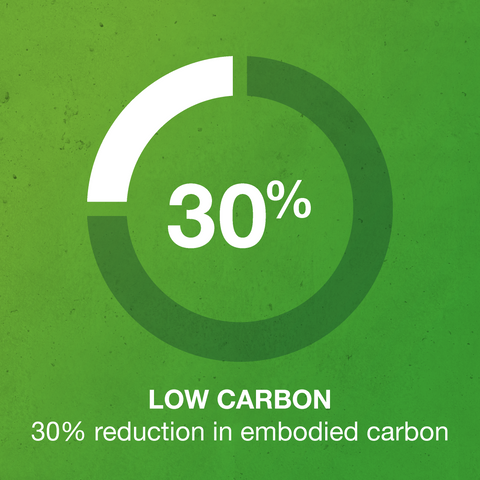

| Low Carbon: This option is available for those who want more certainty with their concrete mix. It incorporates a 30% fly ash replacement 30MPa 19mm aggregate mix, resulting in a ~30% reduction in embodied carbon compared to standard mixes. |

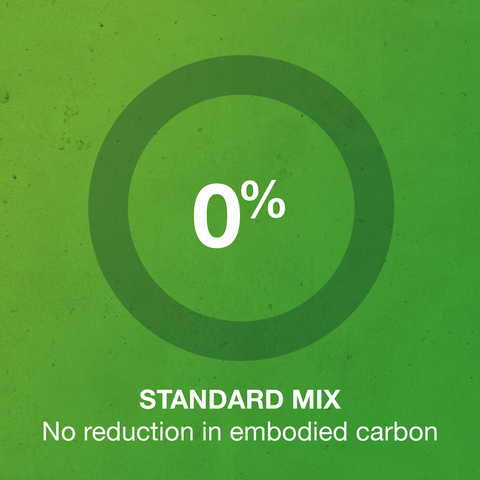

| Standard Mix: This mix is ideal if you have specific manufacturing timelines and/or technical requirements. This option features a standard 30MPa 19mm aggregate mix with no carbon reduction. |

The Benefits of TPS

TPS gives you and the environment access to many benefits:

- Improved Consistency: TPS gives you confidence to specify Envirocon blocks for your projects. Giving you the choice of concrete mixes means you can control design outcomes more effectively.

- Improved sustainability: TPS helps you meet your sustainability targets by providing options for ultra-low-carbon and low-carbon concrete mixes.

- Reduced embodied carbon: TPS can significantly reduce the embodied carbon of construction projects. The most effective is the ultra-low-carbon-mix followed by the low-carbon mix.

Greater design flexibility: TPS allows you to balance the technical requirements of consistent concrete mixes against potential sustainability impacts.

Envirocon's Commitment to Sustainability

Envirocon is a leader in construction sustainability. Our comprehensive circular economy approach incorporates:

- Accredited product stewardship

- Design for deconstruction

- Low-carbon products

- A registered EPD

- A unique buyback guarantee

Giving You Concrete Choices & Easy Sustainability Solutions

Adding TPS expands your options, making it easy for you to have well-engineered and sustainable choices. With TPS, you can control design outcomes, reduce embodied carbon, and make informed decisions about your project's environmental impact.

If you're ready to take advantage of Envirocon's sustainable concrete solutions and TPS's flexibility, reach out to our team today to discuss how we can work together on your next project.

Sustainability is increasingly shaping up to be a significant driver of change in how we build and operate in New Zealand. Over the past five years a raft of new statutory and regulatory requirements have been passed or come into force.

Legislation such as the Zero Carbon Act, Waste Minimisation Act, Resource Management Act (RMA), and Environmental Reporting Act, have been passed to push a more sustainable approach to managing resources.

We profile some of these in this article, and this blog will guide you through key dates in 2023 and beyond.

Zero Carbon Act

The Zero Carbon Act (also known as the Climate Change Response Act) is one of the most prominent New Zealand Government Acts relating to sustainability. It aims to help limit the global average temperature to 1.5 degrees celsius under the Paris Climate Agreement. This requirement that forms the Act spans decades, so vigilance in knowing what’s coming up is needed.

The largest target for this act is known as “Target for 2050”. This Act requires:

BY THE BEGINNING OF 1ST OF JANUARY 2030:

- Biogenic methane emissions are 10% less than 2017 emissions in a calendar year

BY THE BEGINNING OF 1ST OF JANUARY 2050:

- Net accounting emissions of greenhouse gases (apart from biogenic methane) are 0 in a calendar year

- Biogenic methane emissions are 24% to 47% less than 2017 emissions in a calendar year (and each subsequent year)

POTENTIAL RECOMMENDATIONS TO AMEND 2050 TARGET

With the 2050 target being over two decades away, the Commission may recommend some changes. Keeping this in mind is a good idea to know as it has the potential to impact individuals & businesses.

- The timeframe for achievement

- The level of emission reductions required to achieve

- The greenhouse gases, emissions, and removals

- How the target is met

In order for the Commission to recommend these changes a significant change has to occur. This includes the scientific understanding of climate change, New Zealand’s economy, New Zealand’s obligations under international agreements (like the Paris Climate Agreement), and technological developments.

Waste Minimisation Act

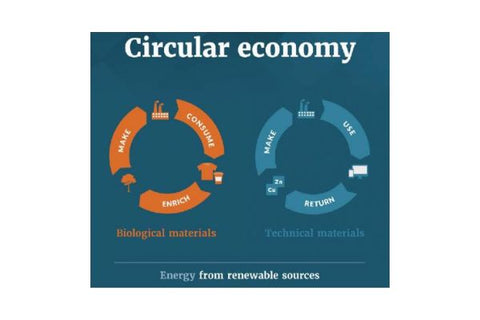

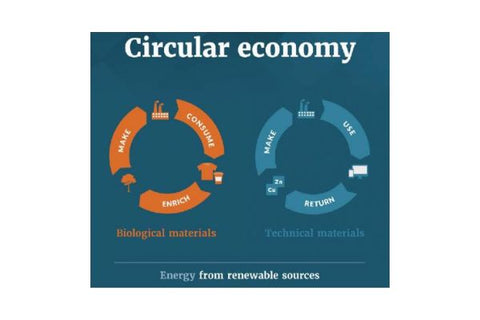

The Waste Minimisation Act aims to push New Zealand towards a circular economy. It encourages a reduction in the amount of waste by putting a cost on waste and encouraging product stewardship.

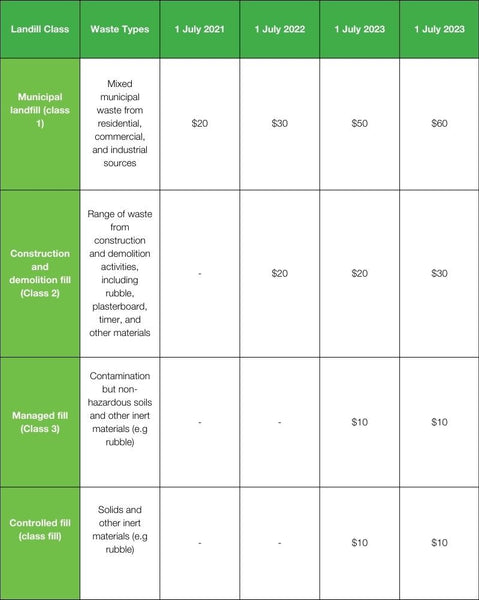

One of the largest components of the Waste Minimisation Act is the Waste Levy. From the 1st of July 2023, this is set to increase. Presently, the increase in levies is set to stop on the 1st of July 2024.

CURRENT, AS OF APRIL 2023

- Municipal landfill: $30

- Construction and demolition fill: $20

- Managed or controlled fill facility: No levy

1 JULY 2023

- Municipal Landifill: $50

- Construction and demolition fill: $20

- Managed or controlled fill facility: $10 (New levy)

1 JULY 2024

- Municipal Landifill: $60

- Construction and demolition fill: $30

- Managed or controlled fill facility: $10

To help support the growth of a circular economy, mandatory product stewardships schemes are being implemented. Product stewardship asks manufacturers to take responsibility for the product at the end of their useful life. By doing this, it’s hoped that manufacturers will design products that maximise resource efficiency and reduce long-term waste.

With product stewardships, there are voluntary and regulated options. Regulated product stewardships are used for the 6 priority products that the Government has deemed a priority. These products are:

- Plastic packaging

- Tyres

- Electrical and electronic products (e-waste including large batteries)

- Agrichemicals and their containers

- Refrigerants and other synthetic greenhouse gases

- Farm plastics.

The upcoming regulated product stewardships are tyres and large batteries. Accreditation for tyres has been completed and is expected to launch in late 2023. For batteries, the accreditation is expected to be finalized in late 2023, with the scheme launching in 2024.

The Agrecoverey Foundation will be consulted on regulations to support farm waste (plastics, Agrichemicals, and their containers) in late 2023.

Resource Management Amended Act 2020

The purpose of the existing RMA is to balance the economic and environmental trade offs in resource use.. Not only does the RMA manage air, soil, fresh water and coastal marine areas, it also regulates land use and the provision of infrastructure that are integral to the country’s planning system (Ministry for the Environment)

Over the coming years, the RMA is getting a major overhaul. Three pieces of legislation are planned to replace the current RMA (Resource Management Act 1991). They are:

- Natural and Built Environment Act (NBE Act), the main replacement for the RMA, to protect and restore the environment while better-enabling development

- Spatial Planning Act (SPA), which requires the development of regional spatial strategies (RSSs) and implementation plans, to help coordinate and integrate long term-strategic decisions in each region

- Climate Adaptation Act (CAA), to address complex issues associated with managed retreat.

Confirmation of these changes is expected mid-2023. Soon after the new legislation comes into force the Government will release the National Planning Framework (NPF) which will provide more detailed national direction on how decision-makers in the new resource management system will give effect to the new legislation. The intention is that this comes into effect in early 2025.

Resource management reforms will play an instrumental role in planning for natural hazards. The NPF will provide national direction on risk reduction and resilience to natural hazards and the effects of climate change. The NPF will guide regions on how to undertake risk assessments, respond to, and prepare for future hazard and climate events, supporting consistency across New Zealand.

How Envirocon Is Helping Build a Greener Future

Since we were established in 2004, we’ve always been working towards building a greener future. With all of the changes coming to sustainability Acts and agreements, here is we make following the changes easy.

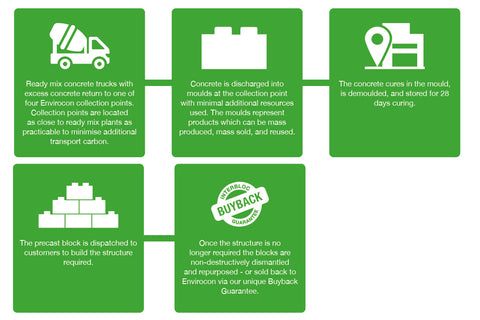

Our Interbloc concrete blocks are low carbon, zero waste (They’re CarbonSmar®t). At the tail end of 2022 we were independently verified with an EPD demonstrating we’re New Zealand’s only precast construction system that has a low carbon profile. This is made possible with a voluntary product stewardship that we have with leading concrete suppliers - we take high-quality, wet excess concrete that would’ve otherwise ended up in landfill and pour it into our Interbloc moulds. Using this concrete means fewer emissions are created, helping support New Zealand's construction industry to achieve the 2050 Zero Caron Act targets.

By using high-quality, wet excess concrete, we’re avoiding another waste stream being created. With the help of product stewardship, Interbloc works towards accomplishing the desired outcome of the Waste Minimisation Act - to reduce waste. Both of Envirocon’s ranges - Interbloc and Stonebloc - are modular concrete block systems meaning structures can be deconstructed when they’re no longer needed. Having solutions that are modular reduces the need for more materials/products being created, further supporting the Waste Minimisation Act.

For a solution that works with New Zealand’s sustainability acts & agreements, ask about Interbloc or Stonebloc.

The amount of waste New Zealanders are sending to landfill is increasing. In the last decade, disposal in municipal landfills has increased by 48% (Ministry for the Environment). In Auckland alone, 1.6 million tonnes of waste is sent to landfill - more than 1 tonne per person (Auckland Council).

Only a small fraction of New Zealand's waste is reused or recycled because

- It has become much more difficult to send waste overseas for recycling with recent restrictions on importing waste for recycling, and dramatic price falls for materials for recycling in international markets; this has particularly affected recycling of plastics, paper, and card

- There is limited infrastructure in New Zealand for recycling and reusing waste

- Many products are not designed to be reused or recycled

- It is often much cheaper and easier to dispose of materials to landfill than to reuse them

One of the tools that local councils and central governments are using to combat this is waste levies.

What are waste levies?

To help New Zealand take responsibility for the waste they produce, tools like waste levies are being implemented.There are 2 main aims of creating waste levies: to raise revenue for initiatives that aim to reduce and encourage resource recovery, and recognize that waste disposal imposes costs on the environment, society, and the economy (MFE).

Over a duration of 4 years, the levy will be progressively increased to allow for behavioural change and system implementation.

There are 4 types of landfill that the central government has levies for or is adding waste levies to. These are municipal waste (current), construction and demolition waste (current), managed fill, and controlled fill. By July 1st 2024, the waste levy for municipal waste will be $60 per tonne, construction and demolition waste $30 per tonne, managed fill $10 per tonne and controlled fill $10 per tonne.(Waste Management).

How waste levies are distributed in New Zealand

Revenue raised from the levy is to be spent on waste minimisation activities. The process of how it needs to be spent:

- Firstly, any refunds are paid to operations of levied facilities. This happens when a levy payment has been waived

- Next, half of the remaining money is allocated to territorial authorities e.g local councils) on a population basis. This revenue needs to be spent on achieving waste minimisation (or promoting it) as set out in their waste management and minimisation plans

- Next, all administration costs are paid. Administration activities include the cost of collecting the levy and distributing funds to territorial authorities or through the Waste Minimisation Fund

- Any remaining levy revenue is allocated to waste minimisation projects, generally through the WMF.

THE WASTE MINIMISATION FUND

This fund is used to build recycling infrastructure across New Zealand. A long-term plan for managing the country’s waste and how the increased revenue will be spent is being strategized by the Government (EnviroWaste). Likely, this will include large scale investments in recycling and other alternatives to landfill combined with smaller-scale initiatives for innovative approaches and increasing public awareness.

Envirocon’s Role in Waste Levies; Using Product Stewardship

Envirocon is the concrete industry’s answer to eliminating waste. In 2015 we created the Envirocon Product Stewardship Scheme with New Zealand’s leading concrete suppliers. Accredited by the Minister for the Environment under the Waste Minimisation Act 2008, wet excess certified concrete is upcycled - eliminating a waste stream and reducing associate cost.

The future of waste levies in New Zealand

As of June 2022, revenues raised from the landfill levy is about $36million per annum - and it has to be spent on waste minimisation. Increases in the waste levy is projected to reach between $220 and $247 million by 2023 (Ministry for the Environment). This gives more revenue for waste management and waste minimisation activity.

For New Zealand to have a low-waste future, there is a high demand to develop large-scale resource recovery infrastructure. Rather than exporting our waste overseas, we need to deal with it ourselves. Some of these actions (that use revenue from the waste levies) may include:

- Increased on-shore processing and manufacturing capacity for materials like plastics, paper, and glass

- Greater investment in improving the quality of our recycling commodities(this includes enhancing systems for collecting and sorting materials)

- More extensive networks of resource recovery centers, including construction and demolition materials

Envirocon’s Interbloc range helps achieve waste minimization goals

Interbloc’s refuse and recycling bins can help New Zealand get closer to achieving these actions. By choosing Interbloc for resource recovery centers, a host of benefits are obtained:

LOW CARBON, ZERO WASTE

Every year about 300,000 tonnes (or seven sky towers) of high quality, certified concrete ends up as waste. Interbloc helps to change that with its CarbonSmart system, closing the loop on concrete waste for good.

Because Interbloc is made for wet, certified excess concrete it’s low carbon, zero waste. Backed by an EPD, Interbloc supports the goals of reducing waste as well as other acts like the Waste Minimisation Act 2008, Zero Carbon Act, and the Paris Climate Agreement.

By using Interbloc for your refuse and recycling bins, you are helping New Zealand reduce was in 2 ways:

- The wet certified excess concrete is used to create Interbloc, diverting from landfill (and avoiding a waste stream)

- The blocks are used to create the infrastructure to manage New Zealand’s waste

MADE FOR DECONSTRUCTION

Interbloc is a modular precast construction system, meaning blocks can be easily stacked and unstacked. This makes the Interbloc system, one that’s purpose-built for deconstruction. Thanks to the interlocking shear key in every block, blocks can be sold back to us via the buyback guarantee after you’ve finished with them.

Combining the low-carbon elements of Interbloc along with its ability to deconstruct, a circular economy is created.

The modularity of Interbloc means that it can grow or shrink to New Zealand’s waste needs. It can be used initially to sort and store waste, but if there is a reduction in waste and a lack of need for bins, you can non-destructively dismantle the blocks and stop more waste from entering New Zealand’s landfills.

CODE COMPLIANT

Interbloc is backed by comprehensive, code-compliant, structural design methodologies. If needed, PS1s can also be issued.

To fit different engineering and council requirements, there are many configurations and solutions available with Interbloc. The modular system can be vertically reinforced to form a cantilever wall which increases the loads the walls can take.

By using Interbloc for waste management & minimisation structures, you’ll have a strong and safe solution that will stand for years to come.

HIGH PRODUCTIVITY

New Zealand needs to act fast to effectively reduce waste; Interbloc can help.

From the start, Interbloc has been designed to be a high productivity precast modular wall system. This means you can install more walls with less effort compared to other systems. Achieving the productivity of 160m2 of wall per day (with 2 people), is all done with the interlocking shear key.

Choose Interbloc to help New Zealand become more sustainable

New Zealand needs a waste management and minimsation solution that is adaptable, sustainable, and strong. Interbloc offers this and more.

Reach out to us today for a quote.

The increasing demand for sustainable and resource-efficient construction processes presents significant opportunities for specifiers, suppliers, and contractors to transform their business practices for the better. This demand is fueled by several factors, including the government’s desire to reduce carbon emissions. The ultimate goal of sustainability is to ensure that we do things today in a way that can be sustained for the future. At Envirocon, we understand that these changes can be painless, practical, and cost-effective, as we have successfully implemented them for the past 18 years.

A Practical Approach to Sustainable Construction

Implementing sustainability doesn't have to be a daunting task, but it often requires partnering with experts in the field. This is where Envirocon comes in. Approximately 300,000 tonnes of high-quality, certified, wet concrete - equivalent to seven Sky Towers worth - would go to waste because it cannot be used before it cures. Envirocon was established to eliminate this waste. We work closely with some of New Zealand's largest concrete companies to permanently close the loop on concrete waste by transforming excess high-quality concrete into precast concrete products that can be reused repeatedly. Our expertise lies in matching insecure and volatile supply with mass market demand. We do the hard work on sustainability so our customers can unlock exceptional benefits.

Accreditation Matters, Avoid Greenwashing

When there is a demand for a solution that is not readily available, there may be a temptation to offer an inadequate response, which is known as greenwashing in the sustainability world. Greenwashing occurs when a proposed solution may sound good but ultimately fails to make a significant impact. Specifiers, contractors, and asset owners need to feel reassured that their sustainability initiatives are genuinely effective.

Envirocon serves as an example of how to achieve this. Our company operates New Zealand's only construction-related Product Stewardship Scheme, which has been accredited by the Minister for the Environment under the Waste Minimisation Act 2008, demonstrating our zero-waste approach to handling excess concrete. Additionally, we have a registered Environmental Product Declaration that establishes the ultra low embodied carbon profile of our blocks. These two independently verified accreditations provide a comprehensive sustainability solution for contractors striving to fulfill complex and ambitious sustainability objectives.

It’s Only Going to Get More Important

By putting carbon reduction plans into action, we can help mitigate further impacts including slowing down global warming. The average global temperature is projected to increase by 1.5°C above pre-industrial levels by 2040, and without immediate and significant action, the impacts of climate change will only become more severe (Intergovernmental Panel on Climate Change).

Creating more resource-efficient practices also supports a more sustainable planet. By shifting focus to resource efficiency, it’s estimated we can reduce the use of raw materials by 60% and the costs of waste management by up to 90% (European Commission). Choosing solutions that enable the ability for resource efficiency will help achieve these estimates.

Sustainable construction is a topic of growing importance, and the New Zealand government has enacted two critical pieces of legislation regarding carbon reduction and resource efficiency: the Zero Carbon Act and the Waste Minimisation Act.

Enacted in 2019, the Zero Carbon Act sets a target for New Zealand to achieve net-zero carbon emissions by 2050 and establishes an independent climate commission to provide guidance on accomplishing this goal. The Waste Minimisation Act, enacted in 2008, promotes waste reduction, reuse, and recycling, with the goal of conserving resources.

Envirocon and its product ranges demonstrate how compliance with these Act’s can be achieved without needing to reinvent the wheel;

- Reusing wet excess concrete that would otherwise be sent to landfills, resulting in low-carbon, zero-waste Interbloc as the carbon cost has already been assigned to the project from which it originated.

- Creating Interbloc and Stonebloc to be dismantled with fewer new materials needed, thereby producing less carbon.

- Reusing wet excess concrete and preventing it from being sent to landfills.

- Offering modular concrete blocks that can be used repeatedly without being discarded, minimizing waste. This create a circular economy.

Practical Sustainable Construction Case Studies

CITY RAIL LINK

The City Rail Link - a huge infrastructure project - aim’s set the benchmark for developing sustainable infrastructure in New Zealand. Following the ISCA framework, carbon reduction and resource efficiency are some of the projects’ highest priorities.

Envirocon and the Link Alliance started working together as soon as construction commenced in 2019. Link Alliance was able to get certainty excess concrete was diverted from landfill - helping to achieve the zero waste goals of the project, and at the same time reuse low embodied carbon blocks on the project.

Nick Braxton is the Principal Sustainability Advisor for the Link Alliance. He explains that the Alliance has a “zero waste to landfill” policy that makes Envirocon a perfect partner for them. “Our non- linear approach to waste management means we’re using excess concrete for a wide range of purposes instead of sending it to landfill,” he says.

As the project comes to an end, the intention is to take the blocks back off the project and repurpose them for other structures.

WATERVIEW TUNNEL

The $1.4 billion project, the Waterview Connection, includes the construction of 4.8km of six-lane motorway. To achieve this, extensive tunnelling needed to be conducted resulting in plenty of excess water.

Interbloc was contracted to form the settlement ponds for this project, largely due to the engineering capacity of the concrete blocks and that they could be removed easily after the project finished via the buyback guarantee.

By using Interbloc for their settlement pounds, the Waterview Connection was able to be resource efficient.

Key Lesson - Sustainability Doesn't Have to be Hard

Envirocon demonstrates how partnering with the right suppliers can deliver innovative and comprehensive sustainable construction solutions which don’t necessarily need to be difficult, expensive, or lower quality.

Are you in the events industry and looking for a way to add brand identity and functionality to your concrete blocks? Our new 'brand your block' service is here to help.

We can customise the look of a block so suit your brand by sticking decals to the side of the blocks. These high-quality decals are perfect for branding and customizing all of our counterweight and bollard ranges, from 10kgs to 1500kgs. They're great for a variety of events, including weddings, parties, and corporate events. With our decals, you can transform your blocks into unique and personalized pieces that will make your event stand out.

(BollardBloc on the left and a decal for Tomo's Saws and Mowers on the right)

Here are a few ways you can use our 'brand your block' service:

- Use them as counterweights for marquees and tents, ensuring stability and safety

- Use them as weights for signage and banners, keeping them in place even in windy conditions

- Use them as bollards to create barriers and define spaces

- Use them as hoardings to create a backdrop or partition

- Use them as seating, adding a pop of color and personality to your event

The decals are made with a special adhesive that ensures they'll stay put with a 12 month warranty. They are easy to apply and remove.

We offer both hire and buy options for the concrete blocks. If you're wanting to hire, any decals will be yours and are not part of the hiring process. Buying online will be offered soon but for now contact us, we will be able to help you to buy bundles of blocks with customised decals that fit their brand.

So why settle for plain, boring blocks when you can add some style and functionality with our decal service? Contact us today to start branding your blocks, elevating your space with unique and personalized concrete blocks for any occasion.

The Paris Climate Agreement, also known as the Paris Agreement or COP21, is a legally binding international treaty adopted by almost every country in the world in 2015. Its goal is to limit global warming to below 2 degrees Celsius above pre-industrial levels and to pursue efforts to limit the temperature increase to 1.5 degrees Celsius. In order to achieve this, countries have committed to regularly reporting their greenhouse gas emissions and implementing measures to reduce them.

As the world shifts towards a more sustainable future, there is an increasing demand for products and services that can help reduce carbon emissions and create climate resilient economies. Products like Interbloc and Stonebloc are leading the way in this regard by providing innovative building solutions that can help to meet the needs of the Paris Climate Agreement while following the principles of circular economy.

Interbloc, with its precast concrete blocks using wet excess concrete, is an excellent example of circular economy in action. By repurposing excess concrete, Interbloc is not only reducing the environmental impact of concrete production but also saving costs and resources. They are keeping the resources in use for as long as possible and extracting the maximum value from them before recovering and regenerating the products. Interbloc also offers a buyback guarantee, which means they will repurchase any used blocks at the end of their useful life, ensuring that the blocks will be repurposed, completing the loop of the circular economy.

Not only that, but Interbloc blocks are energy-efficient, durable and modular. This means that they can be easily assembled and disassembled, making them ideal for construction projects that are subject to change, such as temporary structures or phased developments. This is particularly useful for reducing waste and minimizing construction time, and it can help to create climate resilient economies by providing durable and sustainable building solutions that can withstand the effects of climate change.

Stonebloc is another range in the the Envirocon catalogue, with a focus on timeless aesthtics. It’s designed to be used in a modular system, which allows for flexibility and adaptability in construction projects, helping reduce waste and minimize construction time. By offering durable and sustainable building solutions, Stonebloc plays a role in creating economies that can withstand the effects of climate change

Both Interbloc and Stonebloc are examples of how businesses can play a role in meeting the needs of the Paris Climate Agreement by providing innovative solutions that can help to reduce carbon emissions, repurpose waste materials, and follow the principles of circular economy. They also help to create climate resilient economies by providing durable and sustainable building solutions that can withstand the effects of climate change. They show that it is possible to have a thriving economy and a healthy environment, and that businesses have a responsibility to contribute to the global effort to combat climate change and to promote a more sustainable future.

As we kick into 2023, we thought it'd be a great opportunity to look back at the challenges and achievements of 2022 and highlight our focus for 2023.

In many ways, 2022 was a year of preparation. From manufacturing to sales and marketing, significant investment was undertaken to prepare Envirocon for future growth.

On the operations side of our business we continued to expand our engineering capacity, doubling the mould-making team in preparation for new collection points and manufacturing locations to be opened. Late 2022 saw the opening of East Tamaki, and as we return to work January sees the opening of Timaru and Cromwell. We’ll target to open an additional three locations over 2023, bringing manufacturing closer to our customers and lowering the cost and environmental impact of freight.

We also put a big emphasis on product development and R&D , as a result 2023 will see Envirocon launch three new Stonebloc products to round out the range and offer a complete solution. We’ll continue to launch new and improved counterweight block designs in larger weights. Finally, we’ll be launching an improved version of the Stonebloc standard block, incorporating more tolerance into the block, improving the installation experience.

Ram raiding across the country provided the opportunity to showcase the flexibility of our concrete blocks. We combined the strength of our 1000KG concrete block with a timber seat to help Kiwi businesses protect their assets, creating BollardBloc.

A core focus for the company is continuing to improve the ease of design and use of our Interbloc and Stonebloc construction systems. 2022 saw the launch of Envirobuild, a custom built, cloud based 3D design software system that dramatically speeds up the design of Interbloc and Stonebloc structures. Envirobuild quantifies the blocks required for the design and creates high quality 3D visualisations of structures that can be explored by third parties via our Envirobuild Viewer functionality. As we move into quarter one of 2023 we’ll be launching Envirobuild for public use.

As foreshadowed at the beginning of 2022, sustainability continues to sit at the core of our business. We completed and registered NZ’s first precast concrete Environmental Product Declaration (EPD) which demonstrates the very low embodied carbon footprint of our precast construction systems.

The registration of our EPD rounds out our CarbonSmart® sustainability story - arguably the most comprehensive approach to sustainability in NZ today. Our focus for 2023 will be to spread this message to larger audiences, bringing the benefits of fast, efficient, durable construction with impeccable sustainability credentials to organisations facing increasing demands from government and asset owners.

We’re excited to announce the launch of our first Environmental Product Declaration (EPD) for our Interbloc precast construction system.

Our EPD is unique in a number of ways;

- It’s the first EPD in NZ to cover precast concrete products

- It demonstrates low embodied carbon footprint for our precast elements

- It demonstrates the impact of zero waste design, and benefits of recarbonation at end of life

In April 2022, we approached thinkstep-anz - leaders in product life cycle assessment and sustainability- to produce an EPD for Interbloc. This would focus on manufacturing with Envirocon’s CarbonSmart® sustainability system.

"Congratulations to our client EnviroconNZ for rounding off the year with a published EPD for their pre-cast concrete blocks. [Envirocon] design these blocks to reduce construction waste and make them from quality concrete that would otherwise be wasted. Less waste. Tick. Low embodied carbon. Tick. CO2 reabsorbed over their life. Tick. Lots of things to love! It’s been a great project to be part of."

The launch of the EPD shows our unique and unrivaled combination of sustainable features & benefits;

- Product Stewardship - we’re NZ’s only construction related accredited product stewardship scheme diverting high quality concrete from landfill.

- Low Carbon Construction - our CarbonSmart construction systems provide a very low embodied carbon footprint for concrete construction as demonstrated by the EPD.

- Recarbonation - our blocks reabsorb carbon throughout the structure’s life

- Zero Waste through Deconstruction - our structures can be non-destructively dismantled and reused via our unique buyback offer.

Our systems also delivers;

- Fast, Easy Installation - two people can build up to 160m2 of wall per day using standard equipment.

- Code Compliant Engineering - orthodox engineering design allows simple design and consenting processes.

- Safety and Durability - our precast elements are manufactured from high quality certified concrete, incorporating standard certified precast lifting anchors with a FoS >5 for multiple lifting.

- Proven System - in market since 2004 with over 4000 structures built throughout NZ and Australia.

About Environmental Product Declarations

EPD’s are a recipe for the environmental footprint of a product. It is not an endorsement, but provides a level playing field for the comparison of products. In addition EPD’s can make the process of reporting on products and projects through sustainability rating schemes such as the Infrastructure Sustainability Council’s IS Rating Scheme easier.

“An Environmental Product Declaration (EPD) is an independently verified and registered document that communicates transparent and comparable data and other relevant environmental information about the life-cycle environmental impact of a product.

Multiple datasets are included in an EPD: resource consumption of energy, water and renewable resources, and emissions to air, water and soil. This data is aggregated using multiple environmental impacts including contributions to climate change (carbon footprint), air, water and soil pollution and resource depletion.

Other relevant impacts and environmental information may also be included. This may include data on product performance, the company’s environmental management system or other environmental certifications.”

(EPD Australasia, 2023)

About Envirocon

Envirocon is a sustainability-driven precast concrete company that supplies easy to use, fast and flexible construction systems.

We work with NZ’s leading companies to close the loop on concrete waste for good.

We do this through our Interbloc and Stonebloc precast wall systems. At the core of the systems are proprietary block designs. The block designs look simple enough, but when you dive deeper they deliver a powerful combination of benefits.

(Interbloc pre-cast concrete blocks on the left, and Stonebloc retaining wall blocks on the right)

They start life with ultra low embodied carbon, and continue to reabsorb carbon over their life.

They reduce time, labour, and materials waste during installation.

They deliver unparalleled durability, increasing the life of the structure.

They can be non-destructively dismantled and reused at the end of life.

We call this approach the CarbonSmart - Low Carbon, Zero Waste sustainability system.

Envirocon’s delivery service is a great option for those looking for a convenient way to get our blocks to the site. Envirocon freight can be delivered with flexible dates and can help reduce costs.

We have put together a list of our top tips for a smooth delivery of blocks. Applying these tips will help reduce the time of unloading blocks while ensuring everyone’s health and safety. These tips will also help make the dispatch process as easy as possible, even when sites are trickier to access.

Check the Truck

Before we organise dispatch of the blocks, ensure your contractor has checked that an average- width truck (about 2.55 metres) can access the site. You can do this by requesting your contractor to visit the site and by providing them with accurate information. This is important as the contractor then informs the Envirocon Sales and Dispatch Teams. Doing this check will help the ensure the most efficient and timely delivery. You don’t want to find the truck cannot fit into the site after we have sent the blocks!

However, if you find the truck cannot access the site, you will need to request a small vehicle, such as a forklift or excavator, to bring the blocks from the truck to the location.

The Type of Truck Matters

Take the time to plan the type of truck you will need, considering the size, your order tonnage, and accessibility of the site. This will help reduce back and forth of communication between you and us. For example, if you have limited space, you would want to avoid using a curtain sider. Different trucks will be able to carry different max tonnage and it is important to understand not every truck will suit every project, order, or site.

Some of the common truck tonnages are 10, 14, and 28T. Our Envirocon trucks allow for a tonnage capacity of between 10 and 14 tonnes.

(Envirocon trucks ready to start dispatch)

The Gradient is Important

The gradient, or the steepness of the site, is important because it may inhibit the delivery and construction of the structures. A site that is too steep will make it difficult for a truck to access. It also risks safety of the drivers and those on site, given the heavy weight of blocks. Furthermore, if a gradient is too steep, there is a risk of the truck tipping, creating another safety concern. We do not want to risk any accidents or someone getting hurt. So if you do have a steep gradient on your site, let us know. We'll work with you to find a solution.

(

(

Check for Other Factors that Could Affect Site Access

Remember, an entire truck must be able to access the site for the delivery of the blocks to proceed and be successful. Before the truck dispatches, “sweep” the site and check to see if anything else could make the site inaccessible to a truck. For example, narrow access and overgrown trees.

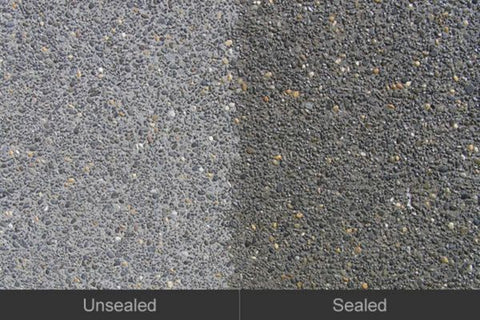

Also, make sure your driveway has been completely sealed. Unsealed driveways make delivery difficult, of course, since a truck needs to drive onto the site. You don't want the truck to sink into the soft concrete.

Following from this, make sure you unload the blocks onto solid ground. Do not place the blocks on soft, wet soil or ground.

Sufficient Storage Space

Stonebloc pallets are large and can take up a lot of space at an area of 1m2 per pallet. Before you unload the pallets, make sure you have selected and organised a large enough space to store the blocks between the installation process.

Pallet Placement

Speedy and efficient installation is one of our primary goals as it reduces labour and makes the process more cost-effective. If you can place the pallets along the length of the planned wall, this will reduce the time to construct the wall. This is because it reduces double handling and the additional manual labour of moving blocks more than necessary.

Consider Delivery Time

When you place a delivery order with Envirocon, your Envirocon representative and Envirocon’s freight supplier will help you organise your delivery date. Try to book your delivery date as soon as possible. This will ensure you can avoid any unnecessary delays, helping you construct the wall sooner.

Dispatch, delivery and unloading of Envirocon’s concrete blocks can be a simple, stress-free procedure so long as you're prepared. It is important to ensure the site is accessible and meets the requirements to avoid any delays and extra costs.

In the wake of the pandemic, the cost of materials, freight, and resources have been a concern for many in the construction industry. With the ever-growing demand coming from the South Island, Envirocon came up with a solution that would meet the growing demand for concrete blocks in the area and decrease freight costs.

Our Christchurch yard has its own manufacturing facilities; it is a self-sufficient plant which allows us to minimise the costs, time and simplify processes. This positively impacts our South Island partners and their growing businesses.

We have put together a list of the benefits.

Freight Cost

This yard is a great solution for cost and time efficiency. An important point of our regional strategy is to begin manufacturing closer to customers to reduce freight costs.

The Christchurch yard can even serve lower North Island orders if the process is feasible and more cost effective than North Island freight.

More Stock

With the new yard, we can produce and expand our stock of concrete blocks to meet the demand and needs of more customers and contractors. Many have expressed their concern about our stock in the North Island yards “flying out the door” because of the high demand. The development of our yard in Christchurch will ensure everyone has access to our concrete blocks when you require them, we have increased the production of our concrete blocks. You will not have to wait as long for more to concrete blocks to be manufactured before dispatch.

(Blocks stacked, ready for delivery in the Christchurch Yard)

Both Interbloc and Stonebloc

The Christchurch yard has the capacity and resources to manufacture both the Interbloc and Stonebloc ranges. However, the majority of Stonebloc stock currently still comes from Auckland. We use moulds to produce our interlocking concrete blocks by pouring in high-quality wet, excess concrete. Once the blocks are set within the moulds, we take them out, and leave them for several

days to continue setting before they are ready for dispatch. The yard has a large roof cover, perfect for pouring concrete into the moulds when it’s raining.

(Concrete being poured into Interbloc moulds)

The expansion of the self-sufficient Christchurch yard offers those in the South Island and lower North Island the chance to acquire their Interbloc and Stonebloc faster while not compromising on the cost. Envirocon is also developing yards of matching capacity in Timaru and Cromwell. So, keep an eye out for updates on this exciting news!

In the face of rapid climate change, the construction industry has environmental and sustainability responsibility it must follow. Businesses in the industry must adhere to government regulations like the Zero Carbon Act and the Waste Minimisation Act.

Embodied carbon is the amount of carbon produced to create a structure or infrastructure. Concrete “consumes” most of the embodied carbon produced. The concrete industry must respect the energy expenditure - the amount of energy a material produces over its lifetime.

We offer a solution to sustainability responsibility that pays homage to legal, and governmental requirements, while creating a product that withstands the test of time. We have engineered a product that adheres to government regulations such as the Zero Carbon Act by pouring high-quality, certified excess wet concrete to moulds to form our concrete blocks.

The carbon is associated with the project the concrete it initially came from prior to being added to our moulds. By doing this, we incorporate a circular economy by keeping our resources in use for as long as possible. Closing the loop on concrete waste is our greatest value. We understand that high-quality, excess concrete is a valuable material and we must decrease our carbon footprint by considering the product’s end of life.

We capture the excess concrete while it is still in its wet form, and pour it into our moulds, creating Interbloc precast wall systems. These blocks have powerful benefits as they start life with low embodied carbon and continue to reabsorb carbon over their life. The blocks reduce time, labour, and materials, are durable and have an extended structural lifetime. Structures can be broken down and the blocks reused, creating a circular economy system. We call this approach our CarbonSmart® sustainability system. This system is also financially beneficial with the reuse of resources, instead of having to source new materials. Our systems are designed to make the transition to our products, seamless, low labour, and time efficient.

(Interbloc Landscape Supply Bins for Wyatt's Landscape Supplies)

Interbloc is part of our product stewardship scheme, which is an approach to managing the environmental impacts of materials throughout their life cycle. Striving to utilise all useable wet concrete, we divert it into our Interbloc moulds. This reduces the carbon use and subsequent waste of valuable materials.

Stonebloc is also sustainable because the blocks allow for non-destructive dismantling. Over time, all the carbon produced will be reabsorbed through re-carbonation. Stonebloc was selected by the South Taranaki District Council to build the sea wall at Opunake Beach. Given the previous 1995 wall was prone to disintegration and erosion from the sea water and elements, the council wanted to build a new wall that was durable and able to withstand a coastal environment, increasing the lifetime of the product and the structure overall.

(Stonebloc seawall for Opunake Beach)

A more sustainable solution such as the ones we offer ensure minimal process changes and reduces delays and cost. Our concrete blocks can be used for a range of applications like aggregate bins, retaining walls (Interbloc and Stonebloc), fertilizer bins , and PKE Bins .

Our Interbloc precast wall system is a low carbon, zero waste construction solution that meets government sustainability regulations. It is an environmentally friendly, cost-effective alternative to other concrete designs.

Our precast wall system is a low carbon, zero waste construction solution that is financially efficient in the long run. It also doesn’t require any changes in behaviour when making the switch. The transition is seamless.