Interbloc's Had a Facelift!

Interbloc+ is Purposely Designed for MSE Walls

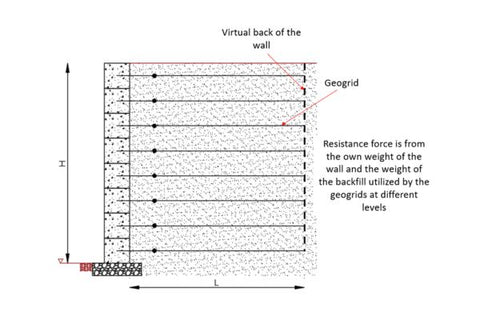

Interbloc+ is designed for MSE walls (although, you can still use these concrete blocks for gravity retaining walls). MSE is a method of reinforcing a wall to withstand high loads. It’s common with bridge culverts and retaining walls above 2.4m. Essentially, it ties the wall elements (Interbloc concrete blocks), to the retained soil using a geogrid matt.

MSE is a faster, more cost-effective, and stronger solution when building retaining walls with large loadings. There are numerous different MSE systems out on the market, however its only when MSE and Interbloc are combined that you truly get the unique benefits of speed, durability, and flexibility.

Benefits of Interbloc+

Interbloc+ walls offer a number of benefits over traditional retaining walls, including:

- Enhanced aesthetics: A split stone facia means the structures you build with Interbloc+ look great and are also well-engineered.

- Durability: Interbloc+ MSE walls are designed to withstand the harshest of environmental conditions, and they are resistant to damage from earthquakes and other natural disasters.

- Rapid construction: Interbloc+ MSE walls can be installed quickly and easily, and the construction process is predictable and repetitive.

- Reduced environmental impact: Interbloc+ with TPS provides a combination of low carbon and high quality

MSE-Wall Specific Benefits:

- Extreme wall heights: Interbloc+ MSE walls can be built to heights of up to 20 metres, making them ideal if you're designing walls with extreme heights.

- Extreme loads can be carried. Interbloc+ MSE walls can carry heavy loads, such as bridge abutment footings or cranes.

- Built-in Geogrid Technology. Interbloc+ incorporates a unique built-in geogrid technology that enhances the overall stability and reinforcement of retaining walls.

Interbloc+ Retains Core Features

Despite its enhanced aesthetics and MSE offering, Interbloc+ retains the core features that have made Interbloc a trusted choice across multiple industries.

- Installation up to 5 times faster than traditional products. Interbloc can be installed at a rate of 160m2 of wall per day with two labourer.

- Interlocking shear key. This feature ensures compliance with the NZS3101 code Part 1 2006 Section 7.5 requirements.

- Up to 97% reduction in embodied carbon compared to other concrete construction systems. Made from high-quality, wet excess concrete, Interbloc is a low carbon, zero waste construction system. It's independently verified by an EPD.

- A minimum of 20MPa concrete or greater. Interbloc utilises high-strength concrete for exceptional durability and structural integrity. Specific concrete mixes can be requested through our Total Precast Solutions offer.

Interbloc+ - Combining Engineering, Aesthetics, and Sustainability.

Interbloc+ is a great choice for your next project. It is a well-designed, aesthetic, and durable retaining wall solution that offers the same benefits and more as Interbloc.

Request a quote today to see how Interbloc+ can help you with your next project.

Finding the right storage solution is vital for New Zealand farmers. Interbloc provides a range of customizable storage solutions that are made for the rural industry. With interlocking concrete blocks forming the modular system, durability and design flexibility are given. Combining this with weather protection, a buyback guarantee, and sustainability accreditation, Interbloc works for the 21st century farmer.

Challenges with Rural Storage

WORSENING WEATHER

New Zealand’s farmers are facing significant weather challenges - from too much rain to drought and from hail to excessive heat (Deloitte). In the first half of 2023 alone, farmers have been impacted by weather events like Cyclone Gabrielle (which caused about half a billion dollars worth of production mainly in agriculture and horticulture). Our rural industry is heavily reliant on the environment, and events like droughts, floods and storms are adding to the list that farmers need to grapple with. With severe weather events increasing, challenges are exacerbated leading to reduced yields, crop failures, and increased costs to farmers (passing on to the New Zealand consumer).

INFLEXIBLE DESIGNS

With traditional farming solutions like sheds and silos, inflexible designs can result in inefficient use of space and wasted resources. Storage solutions that are inflexible make increasing or decreasing grain or feed capacity difficult. Down the line, this can cause revenue loss and reduced productivity.

LABOUR SHORTAGES

Like many instances in New Zealand, the agricultural sector is facing a labour shortage (one of the largest in history). In dairy farms alone, there is an estimated shortage of between 4000 and 6000.

"Late last year DairyNZ did a survey and it had 22 percent of dairy farmers who employ staff saying that they were short-staffed, and on average it was by 1.2 people."

-Dairy NZ Spokesperson Jane Muir

The future of rural storage is modular

In modular construction, building components are made off-site. These components are then transported to site, where installation of the complete structure takes place (Science Direct). Modular construction boasts a list of benefits, all being valuable to the rural industry. From faster installation and higher productivity to less waste and lower costs, modular construction is the way forward. Interbloc is one of these modular systems, giving you these benefits.

Interbloc can be used for a variety of rural applications, most commonly those is the industry build:

- PKE/Feed bins

- Fertiliser Bins

- Silage Bunkers

- Retaining Walls

PKE/Feed Bins

The ability to change the capacity of PKE/Feed bins is important. Interbloc’s modular design allows you to easily change up the capacity of the bin - a 400 tonne bin can be increased to 450 tonne by simply adding an extra layer of blocks.

All in all, Interbloc PKE bins help modern NZ farmers provide a secure and convenient way to manage palm kernel extract (PKE). Getting this storage right improves the feed quality, increases feed efficiency, and saves time on feeding operations.

For best results from an Interbloc PKE/Feed Bins, follow these tips:

- For easier installation, maintenance, and operations, we’d recommend placing your PKE/Feed bin on a concrete pad. Typically around 160-300mm thick depending on the height of the wall and ground conditions

- For a seamless joint between the base of the wall and concrete pad, use Interbloc Flat Bottom Blocks. They come in 1200, and 1800mm lengths

- For waterproofing, use a sealant between the interlocking joints of the Interbloc wall layers

- For weather protection, add a roof to your bin. Typically for these applications, we’d recommend a retractable roof for great useability

Fertiliser Bins

Incorrect storage of fertiliser results in unnecessary wastage, in some cases up to 25% – this is an expensive problem. Getting fertiliser storage right ensures the product retains quality, maximizing their effectiveness in promoting crop growth and yield. Ultimately, this contributes to the growth and sustainability of the New Zealand rural industry.

Interbloc's fertilizer bins address several challenges that modern farmers face. Firstly, with worsening weather patterns, secure storage of fertilizers becomes critical to prevent loss due to flooding or waterlogging. Secondly, with labour shortages, Interbloc's bins offer a modular and easy-to-assemble design, reducing the need for extensive manual labor during installation and maintenance.

Lastly, traditional storage designs can be inflexible and unsuitable for different types of fertilizers. Interbloc's bins, on the other hand, can be customized to meet specific storage requirements, making them a versatile and practical option for modern farmers.

For best results, follow the PKE/Feed Bins tips and:

- Having adequate heat control is vital for fertsilier. Consider adding quality ventilation systems to your Interbloc storage, allowing to maintain a high quality product

- Combine the thickness of Interbloc’s 600mm blocks, roof, and hinged doors to create a solution that limits light exposure. This will also maintain a high quality product

- For bulks fertsilier storage bins, consider adding the 1200 base block to your design. These concrete blocks helps to increase the wall’s load capacities.

Silage Bunkers

Interbloc's silage bunkers offer an efficient and reliable storage solution for New Zealand farmers. The bunkers are designed to withstand the harsh weather conditions that are common in the country, providing long-lasting protection for silage. The modular design of the bunkers also allows for easy assembly and customization, enabling farmers to adapt to changing storage requirements and optimize their silage production.

Before designing your bunker, understand what you want to achieve. Ask yourself these questions

- How much feed do you need to store immediately?

- What are your future plans for the farm?

- How many cows do you have, and how often do you intend to feed them?

- Ensure that you feed across the face of the bunker at least every three days; cutting into the face at 15 – 20cm

More Interbloc Benefits For the Rural Industry

BUYBACK GUARANTEE

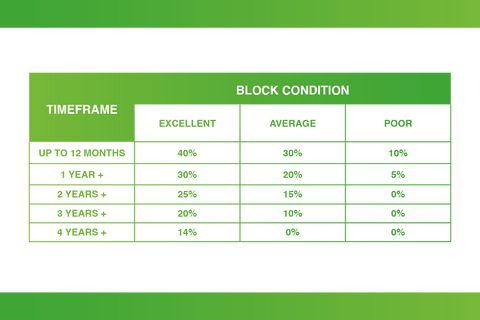

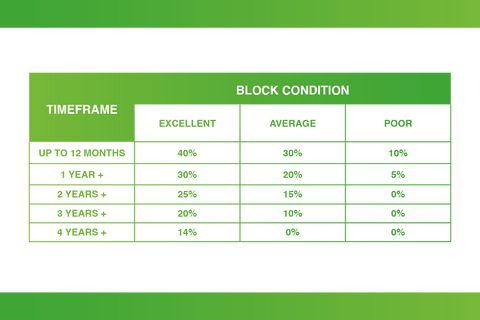

The buyback guarantee gives you peace of mind, allowing you to build for now and plan for the future. If you no longer need your blocks on-site, you can sell them back to us. The offer is:

- We’ll buy back Interbloc manufactured and sold blocks only

- The minimum price is calculated as a percentage of the original purchase price, quality, and age of the block as set out in the table below.

- Blocks originally sold as seconds, rejects, special blocks, flat top, flat bottom, and capper blocks are excluded, however, we may still choose to offer a buyback on these blocks on an adhoc basis.

- The guarantee is only available to the original purchaser and is not transferable

- We may, at our discretion, offer different rates than shown in the table below

LONG-LASTING, STRONG, CERTIFIED CONCRETE

With heavy machinery frequently operating on a farm, you need a storage solution that’s strong. All Interbloc precast blocks are made with a minimum of 20 MPA and are 600mm thick. These concrete blocks also provide a strong solution for the worsening weather conditions across the country.

You can combine Interbloc with vertical reinforcing and/or geogrid for a stronger solution. For these options, you’ll need an engineered design.

FAST INSTALLATION & NON-DESTRUCTIVE DISMANTLING

160m2 of wall can be installed per day with Interbloc, making for a quick solution. This is all down to the modularity of the Interbloc system, giving you the ability to build storage for worsening weather conditions.

By using Interbloc’s modular concrete blocks, you can build strong structures in a fraction of the time compared to traditional storage methods. This means you can do more with less, reducing dependence on manual labour and freeing up time for other essential tasks.

If you need to adapt your designs, or no longer need your blocks, Interbloc can be non-destructively dismantled.

SUSTAINABILITY

We’ve made sustainability easy so you can focus on your day-to-day operations and future planning. Largely, this is done with our low carbon, zero waste interlocking concrete blocks - Interbloc. Independently verified by an EPD, you don’t need to drastically change what you’re doing on the farm to reach sustainability requirements.

Here’s the sustainability acts that Interbloc works with so you don't have to:

- Waste Minimisation Act

- Zero Carbon Act

For 2023 and beyond, Interbloc works rural storage

Interbloc continues to offer practical and reliable storage solutions for the rural industry in New Zealand. With the increasing unpredictability of weather patterns and challenges such as labor shortages, Interbloc's modular and durable designs offer a flexible and sustainable solution. From fertilizers and animal feed to silage and general storage, Interbloc's concrete blocks and bins are designed to withstand the harshest conditions and provide long-lasting protection. As the industry continues to evolve, Interbloc's commitment to quality and innovation ensures that they will remain a trusted partner for farmers seeking efficient and effective storage solutions.

Having proper fertilizer storage is important

To maintain the quality and integrity of fertiliser, good storage is a must (CSBP).Fertiliser is used as a food source for plants, designed to break down in moist conditions so it’s easy to absorb. In order to keep the fertiliser high quality until it’s time to seed, it’s vital that it’s kept dry and safe from harsh weather (Yara).

The requirements for fertiliser storage vary on many factors, including whether the product is placed in indoor or outdoor storage.

| Indoor Fertiliser Storage | Outdoor Fertiliser Storage |

| Best storage practice involves placing the fertiliser in an enclosed building | Store on a raised level, well-drained, dry and smooth surface |

| Needs to be made of a non-combustible material (e.g concrete, brick, or steel) and be well ventilated | All fertilisers that’s stored outside should be protected from the elements by covering. This could be a roof on a bunker, tarpaulin, etc. |

| The floor needs to have a level, dry, and even surface, free from potholes | |

| Typically need more ventilation, which comes with additional cost and maintenance |

Challenges with storing fertilizer

WEATHER PROTECTION

Fertiliser is highly susceptible to moisture, as a result weatherproof storage is a must. Two common approaches to this is the use of an industrial shed or building, lined with concrete to provide a durable corrosion resistant storage solution. For smaller storage requirements, a concrete bunker with a roof is a common solution.

VENTILATION

Getting ventilation right for fertiliser storage is vital - it prevents the buildup of toxic gasses and maintains the product’s quality. In most cases, ventilation is more of a challenge for indoor fertiliser storage.

Largely, ventilation is a more pressing concern for long-term storage. In many cases, sturdy structures made of plastic, metal, or concrete are important. The downside of this, though, is that these structures can be inappropriate for storing organic fertilisers that are still producing methane and other gasses. To combat this, venting or flexible covers are required.

LIGHT EXPOSURE

When light hits most chemical fertilisers, it can break down into a product less valuable. This can even occur after a few hours of exposure. Providing an opaque solution to storage fertiliser is essential in order to maintain a high-quality fertiliser that might react to UV exposure. For outdoor storage, opaque solutions could come with the main structure themselves - made with concrete or timber, for example - and with the roofing. If fertiliser is granular in texture, exposure to UV rays can result in combustion. Keeping fertiliser away from light/UV rays is vital to ensure high quality product (Van Iperen)

HEAT CONTROL

The ideal temperature to store fertilizer in is between 5 and 27℃ (Van Iperen) Compared to light exposure, many fertilizers are far more sensitive to high temperatures. With some fertilizers, they can shift forms or lose the desired quality when exposed to temperatures above 27°C for more than a few hours at a time. At extreme temperatures of 38℃F and above, combustion risks arise from many urea and ammonia-based, nitrogen fertilizers. There’s no need for air conditioning in most fertilizer storage areas, but ventilation can help control both heat and moisture that leads to fertilizer degradation and loss.

MAINTAINING GRANULE SIZE

Fertiliser granules are designed to protect the nutrients contained within, often with a coating that stops air and moisture from reaching the active materials. When granules break down, they lower the fertiliser’s quality. Other compounds may form when this happens, causing too much sodium or heavy metals into the soil. Granules can break down because of vibration/movement from as soon as when the fertiliser is stored.

The benefits of using Interbloc for Fertiliser storage

Interbloc is designed to adapt to your needs and different environments. At the heart of the Interbloc system is an interlocking, precast concrete block. These blocks stack together easily - much like LEGO - to create durable, flexible structures. One common example of these structures are fertiliser bins, but other examples also include PKE/Feed Bins, Silage Bunkers, Retaining Walls etc.

Interbloc fertiliser bins have been designed to provide fast, effective storage with a unique flexibility to accommodate changes in the storage requirements. With over 10 years of experience and hundreds of fertiliser bins around the country, Interbloc is a proven fertiliser storage solution

- Weather Protection: Depending on whether you’re needing indoor or outdoor storage, Interbloc can help. Indoor solutions can be achieved with our bulk fertiliser storage solutions. For outdoor solutions, retractable roofing or hinged doors can be added to ensure ventilation is gained, without sacrificing the quality of the fertilizer.

- Light exposure: With concrete blocks at a minimum of 20 MPA and 600 mm thick, light is very hard to break through. Combine this with a retractable roof and hinged doors for a combination that reduces light exposure with great ventilation.

- Heat control: As you can implement quality ventilation for indoor and outdoor Interbloc solutions, you’ll also be able to maintain a level of heat control

- Maintaining granular size: Because of the modularity of Interbloc, you can adjust your fertiliser bin as you need without much hassle.

By choosing Interbloc for your fertiliser storage, you also gain more benefits including:

- Fast Installation: This is unique to Interbloc. The combination of the interlocking shear key and certified lifting pin means 2 labor units can install up to 160m2 of wall per day. The interlocking shear key allows the blocks to self-align and positive interlock, speeding up installation and increasing the strength of the system.

- Reinforcing options: To improve the capacity of the wall to take higher loads, you can add vertical reinforcing

- Non-destructive dismantling: The modularity of Interbloc means you can deconstruct a wall just as easily as you can build it.

- Buyback guarantee: If you no longer need your Interbloc concrete blocks, you can sell them back to us.

- EPD Backed: With its low carbon profile, Interbloc is independently verified with an EPD from think. This will give you the reassurance that using the concrete block system is sustainable for your projects.

Interbloc Fertilizer Bin Success Stories

Small, Outdoor Fertilizer Bin - Lex Norton

Lex Norton owns and operates the lime prill storage facility for the far north located in Kaikohe. The bin has a capacity of 500 tonnes and was constructed in February 2008 using Interbloc with a simple externally supplied shelter roof.

Interbloc was chosen because:

- The strength of the blocks can withstand the odd hit from the loaded

- The blocks are freestanding

- The bin could be installed with their forklift

- The ability to expand and or relocate the bin in the future

“I was very happy with the Interbloc fertiliser bin and would recommend Interbloc structures for smaller farm storage requirements”. - Lex Norton

Read more

Large, Indoor Bulk Fertiliser Bin - Viterra

Viterra needed to replace their existing retaining walls in their Geelong and Adelaide fertiliser stores, but ran into problems with traditional building techniques. Adding to that was the additional complication of the landlord wanting the 150 x 70 m retaining wall to be removed at Geelong.

Interbloc was chosen because:

- The blocks were movable/ the solution could be temporary

- The Interbloc system is engineered

- The retaining and retention walls that formed the bulk fertilizer storage doubled the factor of safety in their stores

"Viterra was considering a number of solutions. They needed an engineer-designed system and the walls had to be removable. Interbloc provided them with what they needed at a price they were comfortable with. The solution exceeded Viterra’s requirements in every way.” (Blueprint Consulting Engineers)

Read more

Interbloc fertiliser bins offer a practical solution to the challenges of fertiliser storage. Their unique design allows for secure and organized storage, while also minimizing the risk of environmental contamination. If you are looking for an efficient and sustainable way to store your fertiliser, consider Interbloc.

Contact us for a quote and take the first step towards hassle-free fertiliser storage

https://www.envirocon.co.nz/pages/contact-us

Interbloc and timber are materials commonly used for retaining walls across various industries like civil and construction. Both solutions come with their advantages and disadvantages depending on the project. This blog will help you determine which material is best for your current or upcoming project.

Interbloc Precast Concrete Block Walls

Made of wet excess concrete, Interbloc is a low carbon, zero waste precast concrete construction system - it’s CarbonSmart®. Central to the system is an interlocking, modular concrete block. Being modular, Interbloc can work across many applications (including retaining walls).

The features of the Interbloc concrete block system are:

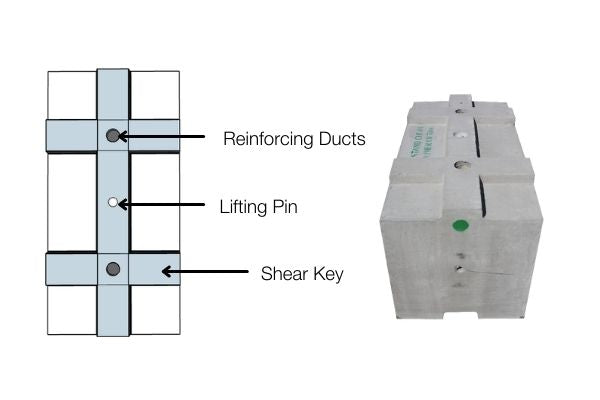

- A shear key: This is unique to Interbloc. The interlocking shear key allows the blocks to self align and positive interlock, speeding up installation and increasing the strength of the system Interbloc blocks are always installed in a running bond pattern.

- Reinforcing ducts: To improve the capacity of the wall to take higher loads, you can add vertical reinforcing

- Certified lifting: For easy block movement and installation, at least one lifting pin is added to a block.

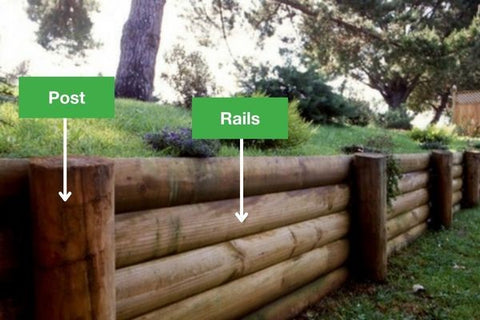

Timber Walls

In New Zealand, cantilevered timber walls are often viewed as the go-to for retaining walls. Not only are they used for residential retaining walls, they are also used for commercial and industrial settings, even as retention walls.

Common features of a timber wall are:

- Posts: These are the vertical pieces of timber that are concreted into the ground.

- Rails: These are the horizontal pieces of timber that retain the soil or act as retention for product

- Concrete: This is used to install the posts and make sure they don’t shift

Interbloc vs Timer: Pros and Cons

Across the board, Interbloc offers you the most advantages and least disadvantages compared to timber walls.

The areas that Interbloc wins out are

- Minimal foundations

- Fast Installation

- No pre-build inspection

- Extended durability

- Non-destructive dismantling

The Pros of Interbloc and Timber

INTERBLOC

Interbloc precast concrete blocks form a modular system full of benefits. One of the noticeable advantages of using Interbloc is the productivity gains. 2 laborers can install up to 160m2 of wall per day. And thanks to the interlocking shear key on every block, you can rearrange as you build. The shear key is what turns Interbloc into a modular system and allows for the speed of construction with the strength of concrete.

Interbloc is unique in that is holds New Zealand’s only registered Environmental Product Declaration for a precast concrete product. This EPD demonstrates that blocks have an ultra low embodied carbon footprint. The result is that Interbloc offers a sustainable alternative to timber. Combining the origin of Interbloc’s concrete with the modularity of the system makes it a perfect system to support a circular economy. If an Interbloc structure is no longer needed, you can deconstruct and sell the blocks back to us via the buyback guarantee.

Interbloc's interlocking blocks are designed for reuse; they’re very durable. Every block in the range is 600mm wide giving you a long-lasting solution. In many instances, concrete is one of the strongest building materials used in construction so be rest-assured your walls will be up for years to come. Durability can also be found with Interbloc’s code-compliant engineering and vertical reinforcement options.

When choosing Interbloc over timber, there are 2 actions you don’t need to consider. The first one being a pre-build inspection. As there are no timber poles being concrete into the ground, council consent is not required in this instance. Compared to timber, there are minimal foundations required. Interbloc structures can be built straight on a concrete foundation, or have vertical reinforcing added to create a well-engineered, strong retaining wall.

TIMBER

Timber is an acceptable solution under the NZ building code, and as such tends to be the go to for retaining in NZ. In most cases, walls under 1.5m do not need to be engineered. Over 1.5m, they need to be engineered in order to be consented by your local council.

In the general sense, adjustments are easy to be made during installation due to the ability to saw down materials as you need. Combined with the relatively light weight of the materials, construction can be completed fast (excluding concreting posts into the ground, which needs to be consented by the council).

The Cons of Interbloc & Timber

The upfront cost of installing an Interbloc wall can be greater than a timber wall. However, there is less maintenance and material replacement required compared to timber walls, so over time Interbloc will be much more cost-effective.

There are 2 main areas where Interbloc outperforms timber: longevity and installation. Even with treatment, timber walls can be suspect to rotting, warping, splitting, or termites. This leads to a building life of between 20 to 25 years (Green Future Construction). Compared to Interbloc, which will last for a minimum of 60 years, timber walls fail in comparison. Short-term maintenance for timber walls is relatively strategy forward - it’s the long-term maintenance that can be difficult.

However, timber lacks the long term durability of concrete. Even with the use of H5 treated timber, as required by the building code, the timber wall will degrade over time. We’ve all walked past a 20-year-old timber wall that is starting to sag forward with rotted rails. The solution in this instance is to replace the affected area or the entire retaining wall, costing you time and money. In contrast to this, Interbloc won’t deteriorate as it’s made from concrete - a generally stronger material than timber.

Which is more sustainable: Interbloc or Timber

INTERBLOC

Interbloc is a low carbon, zero waste construction system. Using a product stewardship, wet certified excess concrete that would’ve ended up in landfill is added to Interbloc molds. As the carbon is already allocated to the project it came from, Interbloc is low carbon. It’s New Zealand’s only precast solution that demonstrates a low carbon profile.

Low embodied carbon is not the only sustainable element of Interbloc. You also get these benefits:

- EPD Backed: With its low carbon profile, Interbloc is independently verified with an EPD from think. This will give you the reassurance that using the concrete block system is sustainable for your projects.

- Non-destructive dismantling: The modularity of Interbloc (achieved through its interlocking shear key) means you can deconstruct a wall just as easily as you can build it. Accessing utilities is easily done, and does not cause waste unlike timber

- Buyback guarantee: If you no longer need your Interbloc concrete blocks, you can sell them back to us. That way, someone else can use them and they’re not adding to New Zealand’s waste problem.

TIMBER

Like concrete, timber can be unsustainable or sustainable. In this instance, we’re talking about sustainable options with timber.

One of the main ways you’ll be able to tell if timber is sustainable is via a timber certification. In the case of New Zealand, this is the Forest Stewardship Council (FSC). This certification looks at how the use of timber and plantations affects the land, and the environment communicates and ensures forest management for future generations. When a forest is properly managed, timber can be one of the most effective carbon-storing materials (ArchiPro). By choosing timber with this certification, you can be assured that you’re sourcing a sustainable solution. In contrast to this, if this certification is not there, it could mean the timber you’re using for your wall is unsustainable.

Timber also works to reduce the planet’s carbon by storing it. In recent studies, it has been found that timber holds up to 95% of carbon even after being in a landfill for 30 years (OneFortyOne). When a forest is properly managed, timber can be one of the most effective carbon-storing materials.

Although the right timber can be sustainable, there are downsides to using it as a structural solution:

- With some fast-growing timber, there is less strength compared to an old-grown tree. Although, this can be somewhat remedied with modification and treatment. This means replacement walls (in the instance of a timber fail) are needed sooner than with concrete structures.

- If you need to deconstruct a timber structure, there is going to be waste and damaged timber. Add to this, if you need to access utilities, you need to break down the whole wall creating waste

- Wood treatment with the aim to improve longevity can harm the environment

Interbloc gives you options where timber doesn’t

Although timber does have its benefits for retaining walls, overall Interbloc is the standout performer. With its modularity, sustainability, and durability, you will have your retaining walls stand for decades.

For long-lasting retaining walls, reach out to us for a quote.

Waterproofing an Interbloc system, made up of precast concrete blocks, is a crucial step in ensuring the longevity and durability of the structure. Interbloc systems are widely used in settlement ponds, retaining walls, bins, and bunkers, among other applications.In this blog, we'll discuss how to properly waterproof an Interbloc system, why it is important, and why we recommend using sealants for most Interbloc structures.

How to seal an Interbloc structure

- Use a suitable sealant: The first step in waterproofing an Interbloc system is to apply a sealant to the interlocking layers of the blocks. The sealant should be applied in layers to ensure complete coverage before proceeding to the next step.

- Seal the joints: The joints between the precast concrete blocks in an Interbloc system are a common point of water ingress. To prevent water from entering through these joints, they should be sealed with the same sealant. The sealant should be applied to the joint in a continuous bead before the structure is put into use. It is important not to apply too much sealant to the joint as it can cause the precast concrete blocks to shift and move, leading to structural issues.

- Regular maintenance: Waterproofing an Interbloc system is not a one-time process. It is important to conduct regular inspections and maintenance on the system to ensure that the waterproofing remains effective. This includes checking for any cracks or damage to the sealant.

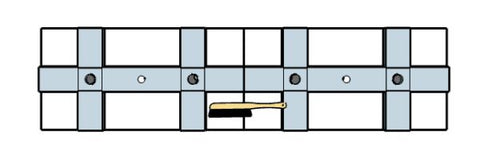

(The highlighted are shows an example of where you'd add sealant if you wanted to waterproof your Interbloc structure)

Why it’s important to waterproof

Waterproofing an Interbloc system is vital because it helps to protect the structure from water damage. Water ingress can cause the system to weaken and deteriorate over time, leading to costly repairs or even complete failure. Waterproofing also prevents structural damage such as rusting of steel reinforcement.

Why we recommend sealants for most Interbloc structures:

Sealants are an excellent choice for waterproofing Interbloc systems because they are easy to apply and can provide long-lasting protection. Sealants are flexible and can move with the structure, which helps to prevent cracking and damage to the waterproofing. Finally, sealants are a cost-effective solution for waterproofing Interbloc systems, making it an attractive option for those on a budget.

Waterproofing the Waterview Tunnel’s Settlement Pond

A well-known Auckland roading project, the Waterview Connection, needed settlement ponds to store and treat liquid from the tunnelling process. Interbloc was chosen for it's combination of engineering and modularity.

In order provide a watertight solution, sealant was added to the joints of the 1.8m high walls. It was sealed using shotcreate, allowing for a temporary solution to hold the liquid. When the settlment ponds were no longer needed, the sealant was removed and the blocks sold back to us via the buyback guarantee.

By taking the steps to waterproof an Interbloc system using a waterproofing sealant, and not applying too much of it, you can ensure that the Interbloc system will remain in good condition for many years to come.

Landslips are a common feature of New Zealand’s 100,000km of roading network, and often affect roads which play a vital role in the day to day lives of local communities. A recent news report put the average number of landslips at 1100 per year - and that's just in Wellington!

(Landslips cause havoc on many New Zealand roads)

When adverse weather events result in landslips, it is essential roading contractors can rapidly clear the landslip and then temporarily contain any supplementary slips while long term solutions can be developed.

Interbloc’s Temporary Slip Protection Wall System provides this safe and effective protection wall from supplementary slips. It is designed to bridge the time gap between the initial clean up and the development of a long term solution - allowing local communities to recover faster.

The blocks can be centrally stored for rapid deployment. Two labour units can build up to 120m2 of wall per day using standard equipment. The wall system is backed by code compliant engineering and a generic PS1 will be issued on purchase. When the wall is no longer required, it can be non-destructively dismantled and returned for storage to be reused over and over.

Key Benefits:

- Rapid Deployment

- Quick Install Time

- Code Compliant and Backed by PS1

- Non-Destructive Dismantle and Reusable

- CarbonSmart® - Low Carbon, Zero Waste

- Aesthetic options available

Interbloc’s Temporary Slip Protection wall system is designed to be simple to deploy, deconstruct, and reuse.

- The system is sold as a package in lineal metres with the option between the practical Interbloc wall system, and a higher aesthetic Stonebloc option.

- A generic PS1 for the design is issued on order covering a specific region and specific customer.

- The blocks are shipped to a location of the customer's choice for storage until required.

- Following a slip, initial remediation is undertaken and the Protection Wall System rapidly deployed to protect against supplementary slips.

- When no longer required, the wall system is non-destructively dismantled and returned to storage for reuse.

Case Study: Liveable Streets East Auckland

Liveable Streets is a joint venture between HEB Construction and Higgins Contracting. Early in 2022 heavy rains resulted in landslides in Whitford, Auckland. With further heavy rains expected, there was an immediate threat to property. There was also the added potential risk of damage to nearby power/utility lines which needed to be considered in the solution’s design. To keep the residents and community safe, a protection wall needed to be erected, fast. Interbloc Precast Concrete Wall System was chosen. When compared to the other options - timber and gabion baskets - it was a no brainer. Both legacy construction systems were too slow to install. In contrast Interbloc allowed for rapid deployment, with trucks rolling in one after the other offloading blocks which were installed in real time. In just 4 days, 337 blocks were installed to build a wall 2.4m high and 20.4m long.

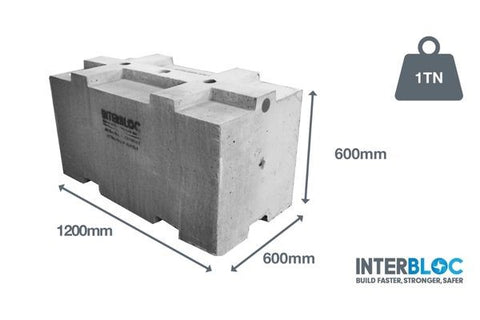

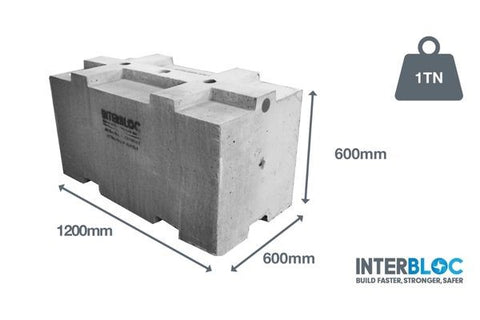

Interbloc is a high productivity, low labour, high quality precast concrete construction system. At the heart of the system is a unique interlocking block which measures 1200 x 600 x 600mm and weighs one tonne. About 80% of an Interbloc structure will utilise this block - what we call the 1200 standard block. However the Interbloc system includes a range of other block configurations, designed to solve specific requirements for your Interbloc build.

Here's a comprehensive list of these block variations.

Flat Top

This block is used on the top layer of a wall to provide clean finishes. Flat top blocks provide wide, flat surfaces to fix structures to (like roofs).

Variations of the flat top block include:

- 1200 Flat Top

- 1800 Flat Top

- 600 Flat Top

Flat top blocks are often used for dry storage with PKE/feed bins and fertilisers bins. They are also added to other applications like aggregate bins.

Flat Bottom

This block is used to ensure seamless connectivity to the structure’s foundation. It allows moisture-critical structures to be sealed from the foundation to the top of the block. This makes it ideal for structures where moisture proofing is essential.

Variations of the flat bottom block include:

- 1200 Flat Bottom

- 1800 Flat Bottom

Ballance Agri-Nutrients Waikato used flat bottom blocks to help create a seamless connection to their bulk fertiliser bin’s foundation.

Angle

The angle block is designed for bins and walls where the wall ‘steps down’ from the top of the structure to the foundation. It provides a smooth and angled front edge to the wall, making a clean finish.

The Viterra Project effectively uses the angle block to ensure health and safety standards were met. It also ensures that material doesn’t aggregate at the top of the walls.

Capper

This block is designed for bulk storage structures, such as fertiliser stores. It eliminates the aggregating of material at the top of the wall. The capper block delivers important health and safety benefits, as it removes the possibility of staff accessing the top of the wall.

Variations of the capper include:

- 600 Capper

- 1200 Capper

Aggregate Bins with 1200 Cappers on top

Base

The base block increases the capacity of the wall, decreases the foundation and bearing capacity requirement of the foundation, is as easy as a standard wall to install. It also has the added benefit of keeping bins cleaner by preventing aggregation of material in corners etc

Fulton Hogan Silverdale

To start building with Interbloc’s specialist blocks, or to add them to an existing project get in touch with us today.

The Interbloc precast wall system is designed with simplicity in mind, because simple systems are fast to learn and easy to use. The blocks stack together with ease and can be vertically reinforced to build strong, durable structures. However, there are some tips and tricks that make installation easier and faster.

This is not a complete guide on how to install with Interbloc, for more information on this please get in touch and we’ll send you the installation guide.

Preparation & Foundation

Clear and easy access to quick unloading

Make sure there is a clear area to unload and install your blocks. Standard Interbloc blocks have a footprint of 0.72m/2 and can be stacked three high. Place the blocks you’ll need first [i.e. flat bottoms] near the front of the stack.

When you’re ready to install, make sure you have the blocks you need near the site of installation. This will make it much easier for you as you won’t be spending as much time getting blocks.

If installing the blocks inside a building and using vertical reinforcing in a wall think about what’s above the wall - fixing kit main bars need clear space equal to the height of the wall to be installed.

Foundation Prep

If you are pouring a concrete slab allow 6mm creep for each block.

It is crucial that you lay a level foundation. If your foundation is not level, it may result in the blocks not fitting together with ease, causing a redesign, longer installation times, and a higher cost to you.

In the event that you have isolated areas of unlevel ground during installation use shims to pack to height.

Placing the first layer

Getting the base layer correct is vital for the ease of placing blocks on higher layers. Run a string line along the length of the planned walls. Use a level to ensure the blocks are sitting correctly in both horizontal directions.

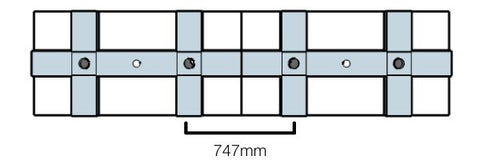

It's critical to ensure the blocks are spaced correctly on the base layer, this will prevent binding in the blocks on higher levels. The gap between the outside edge of the interlocking sheer key should be 747mm (give or take a 1mm either way). This will result in a 3-6mm gap in each block.

The remaining layers

Before you start interlocking blocks, make sure you dust off debris of the lower layer. Debris can cause an uneven surface when interlocking blocks. This can make it difficult to align blocks perfectly and will affect subsequent interlocking layers.

Fixing Kit tips

When using vertical reinforcement in a wall mark out the placement of the fixing kits first. To allow for creep in the blocks the distance from one kit to another should be 603mm. Mark, drill, and install a maximum of 20 starters bars at a time before installing the base layer. This will allow you to recalibrate

Unless otherwise specified in the design, the location of the starter bars should be a minimum of 300mm from the nearest edge of the concrete foundation.

The space between each hole is a minimum of 603mm for 600 series blocks this allows for creep in blocks as the blocks are placed.

If the wall requires more than 20 holes, at the 21st hole recalibrate your measuring tool to ensure accuracy.

Interbloc suggests the use of Chemset™ C8 Extreme or Hilti® HIT-RE 500 epoxies.

One of the unique characteristics of the Interbloc precast wall system is the ability to non-destructively dismantle a structure and reconfigure or reuse the blocks. When you no longer have a need for the blocks Envirocon offers a unique buyback guarantee. It’s a key part of our commitment to practical sustainability and the circular economy. It also means Interbloc customers have an asset with a value at end of the life which is rare in the building materials industry.

What is the buyback guarantee?

The Interbloc buyback guarantee is an offer that allows you to sell back your blocks to us once you no longer need them. Terms and conditions apply.

The offer is:

- We’ll buy back Interbloc manufactured and sold blocks only

- The minimum price is calculated as a percentage of the original purchase price, quality, and age of the block as set out in the table below.

- Blocks originally sold as seconds, rejects, special blocks, flat top, flat bottom, and capper blocks are excluded, however we may still choose to offer a buyback on these blocks on an adhoc basis.

- The guarantee is only available to the original purchaser and is not transferable

- We may, at our discretion, offer different rates than shown in the table below

How It Works in Practice

The Waterview Tunnel project is the perfect example of how Interbloc’s buyback guarantee works. The tunneling process resulted in a slurry which needed to be stored, sorted, and disposed of. Interbloc was used to build a temporary settlement pond on what is now the northbound lanes.

Once the project was completed, the ponds were non-destructively dismantled, with the concrete blocks being sold back to us via the buyback guarantee and repurposed on another project. Innovative approaches to construction such as Interbloc’s buyback guarantee helped the Waterview Tunnel

Linking with sustainability

An overarching goal of sustainability is to maximise the efficiency of resource use. Interbloc’s buyback guarantee lowers the lifetime cost of ownership while limiting waste to landfill.

By selling back your blocks to us, you’re helping to support the circular economy.

Creating a circular economy

The current linear economy takes natural resources, makes things, then disposes of them as waste. The circular economy aims to increase resource reuse through smart design, more durable products that can be recycled or reused.

The Interbloc system is the perfect example of the circular economy in practice. Interbloc utilises high quality excess surplus concrete to wet cast our blocks resulting in low carbon concrete blocks. The blocks are used to construct a large variety of structures from industrial bulk storage, to temporary and permanent retaining and retention walls. When the blocks are no longer required they can be non-destructively dismantled and reused or sold to build yet another structure. The process continues to repeat.

Saving the planet and your wallet

Interbloc’s buyback guarantee combines the benefits of lower lifetime costs and creating a more sustainable New Zealand.

If you've purchased Interbloc in the last 4 years and you want to sell them back to us, get in touch!

The increasing need for sustainable outcomes requires councils to invest in recycling infrastructure. Well sorted and stored recyclables increases recovery rates. However storage must be adaptable and agile - to change with the ever-changing consumption habits of the local population.

Interbloc's CarbonSmart® blocks are used nationwide by the refuse and recycling sector because it it delivers strong, durable, safe storage that can be reconfigured and reused over and over again. It's also a benefit that Interbloc blocks are made from upcycled materials as well.

Current Statistics of New Zealand’s Waste

New Zealanders dispose of around 15 million tonnes of waste per year. This waste comes from a variety of sources, including:

- 3.6 million tonnes (24%) from commercial and industrial sources

- 4.4 million tonnes (29%) from construction and demolition sources

- 1.5 million tonnes (10%) from rural sources

This equals around 3.2 tonnes of waste per person per year, of which only 35% is recovered.

From a global perspective, New Zealand is far behind other OECD countries in terms of municipal solid waste. Where New Zealand recovers 35%, the United Kingdom and Switzerland are 55% and Germany is over 66%. Per capita, we’re also trailing behind other OECD countries. In 2018, it was measured that Columbia, Japan, and Mexico had the least municipal waste going to landfill per capita at approx. 300kg. New Zealand on the other hand was over 700kgs. (New Zealand Infrastructure Commission).

From a global perspective, New Zealand is far behind other OECD countries in terms of municipal solid waste. Where New Zealand recovers 35%, the United Kingdom and Switzerland are 55% and Germany is over 66%. Per capita, we’re also trailing behind other OECD countries. In 2018, it was measured that Columbia, Japan, and Mexico had the least municipal waste going to landfill per capita at approx. 300kg. New Zealand on the other hand was over 700kgs. (New Zealand Infrastructure Commission). These statistics provide insights to where we can improve New Zealand’s resource recovery.

These statistics provide insights to where we can improve New Zealand’s resource recovery.

New Zealand’s plan for resource recovery

There are multiple policies, and forums at play aiming to improve New Zealand’s resource recovery. Most relevant to resource recovery are the Waste Management Act 2008 and the Glass Packaging Forum.

Waste Management Act 2008

This Act encourages the reduction of the amount of waste generated and disposed of in New Zealand. The Act requires councils to develop a Waste Minimisation and Management Plan every 6 years, accredit voluntary product stewardship schemes, and impose levies on waste disposals on landfills.

3R/Glass Packaging Forum

Established in 2006, Glass Packaging Forum (GPF) also promotes the environmental benefits of glass packaging and manages the accredited GPF Product Stewardship Scheme. There are more than 100 member brands that pay levies to the forum related to the volume of glass they put into the New Zealand marketplace.

What’s needed for effective resource recovery

Resource recovery infrastructure is used to extract value from materials at the end of their useful life. The infrastructure requires the collection, disaggregation into separate waste types, processing, and extraction of other resources. This approach follows the circular economy.

The circular economy uses resources with ever-increasing efficiency. It aims to make sure everything we create can be used for as long as possible and then be recycled/upcycled. This process ensures we can unmake everything we make.

With the continuous push to a circular economy from the government, resource recovery needs to be adaptive in the event that a waste stream no longer needs to be recovered. An element that is important in this is the flexibility of design.

Interbloc - A Solution for Resource Recovery

To meet the needs of the private and public sectors, a resource recovery solution needs to be adaptable, quick to install, and sustainable. Interbloc is the ideal solution for both sectors.

Interbloc is a precast concrete wall system, that has an innovative concrete block at its core. The system delivers an unbeatable combination of benefits - they’re fast to install, they’re flexible and can be reconfigured with ease, they’re durable, fully engineered, and carry a market-leading buyback guarantee.

(A standard 1200 Interbloc concrete block)

The buyback guarantee is perfectly suited to resource recovery. With one of New Zealand’s sustainability goals being to reduce waste streams, there is the potential for less resource recovery as resources are better utilises. By using Interbloc’s buyback guarantee, you call sell your blocks back to us if you need fewer/smaller bins.

Examples of Interbloc Resource Recovery

Interbloc has worked alongside many resource recovery organizations. Some of these include Green Gorilla, Envirowaste, Waste Management, Smart Environmental, and the Manawatu District Council. Here’s how we have helped these companies build faster, stronger, and safer with resource recovery structures:

Green Gorilla

Interbloc has been featured in a few of the CID/ Green Gorilla locations including Onehunga, Drury, and the Auckland CBD. Solutions varied from bins, weighbridge barriers, and retaining walls to extra blocks to increase capacity.

To see Green Gorilla’s process, watch the video below. If you have a look at some of the shots, you’ll be able to see Interbloc solutions at work.

Envirowaste

Interbloc Glass Bunkers and Landscape/Aggregate Supply Bins played a key part in solutions for Envirowaste Resource Recovery.

Smart Environmental

The main solution that Smart Environmental has used Interbloc for is glass bunkers. From extending the bins to adding another layer on top, Interbloc has been the system that expands as the company grows.

Manawatu District Council

A transfer station of Interbloc glass bunkers was made for this Manawatu District Council’s resource recovery solution.

Benefits of using Interbloc for resource recovery

- Modularity: You can add/remove material storage easily to fit resource recovery demand

- CarbonSmart®: Interbloc has no extra embedded carbon in the blocks.

- Buyback Guarantee: If you no longer need your blocks, you can sell them back to us to avoid more waste.

- Fits within the circular economy: Allows useful life of the product to be extended and meet the requirements of the New Zealand government

- Follows the Waste Management Act via the product stewardship scheme

Create an adaptive resource recovery solution by choosing Interbloc.

Interbloc is a precast wall system with a unique interlocking concrete block sitting at its heart. These blocks make it fast to install, incredibly durable, and able to be non-destructively dismantled at end of life. The blocks also carry an industry-leading buyback guarantee. All of these benefits are possible thanks to Interbloc’s shear key.

Why is the shear key important to you?

We all want to build faster and stronger without compromising quality and safety. We also want reasonably priced solutions. Precast modular construction systems fit this to a “T”. That’s not to say that all precast solutions offer the same benefits - Interbloc is unique because of the approach we take to design.

We believe great design has people at its core. We think about how you will use the blocks and where you will use them. We think about what will happen at the end of the structure's life, and how we can maximize the use and value of each block. Most of all we think about the safety and stability of the structure. All of this comes together in Interbloc’s shear key.

Shear Key, an Introduction:

Before we get into the specific benefits of shear keys, it's important to cover some terminology first.

| Shear Force | A force acting in a direction that's parallel to (over the top of) a surface or cross-section of a structure. |

| Lateral Forces | A force acting in a generally horizontal direction, such as wind, earthquake, or soil pressure against a retaining wall. |

| Overturning Forces | Overturning moments seek to cause the footing of the structure to become unstable and turn over. |

What is a Shear Key?

Shear keys are used in structures to maintain integrity and improve the strength. Its purpose is to transfer the shear force caused by lateral forces between the structure and the shear key. It doesn’t resist overturning forces. Overturning forces are resisted by the weight of the concrete block itself.

Ranging from bridges to masonry and retaining walls, you may see shear keys in many structures in your life. They all have the same purpose no matter the application - to improve the strength of the structure.

The benefits of a shear key

- Creates a modular solution

- Allows you to non-destructively dismantle one structure and build another

- Faster installation

- Provides resistance against earthquakes

- Resists lateral forces

How Interbloc’s Interlocking Shear Key Works

Interbloc’s shear key uses a cruciform tongue and groove interlocking design, providing an interlocking key in both horizontal directions.

(On the left image is the shear key in blue, on the right is the shear key on Interbloc)

When you're installing a layer on top of your base layer, you'll find the blocks positively locate. By having the shear key in both horizontal directions, installation is easy - much like the popular childhood toy LEGO.

Interbloc’s use of a shear key means you can use it across multiple applications. These include:

- Aggregate Storage

- Bulk Fertiliser

- Scrap Metal Bins

- PKE and Feed Bins

- Silage Bunkers

- Retaining Walls

- Settlement Ponds

- Temporary Foundations

The safety standards that the shear key meets

The main safety standard that our shear key follows is the NZS3101 code Part 1 2006 Section 7.5. This standard relates to the shear strength of members. The members, in this case, are the interlocking concrete blocks.

Read NZS3101 code Part 1 2006 Section 7.5 in this link

If you're wanting a solution that is easy and fast to build, get in touch with us.

Interbloc is primarily a gravity based precast modular wall system. This means the combined mass of the blocks, supported by Interbloc’s unique shear key design, resists forced pushing against the wall. For higher walls, or higher loads, vertical reinforcing can be used to increase the capacity of the wall. All Interbloc blocks incorporate 600mm diameter reinforcing ducts at 600mm centres for speed and ease of installation.

(On the left is an Interbloc gravity wall, on the right is a vertically reinforced Interbloc retaining wall)

What is vertical reinforcing?

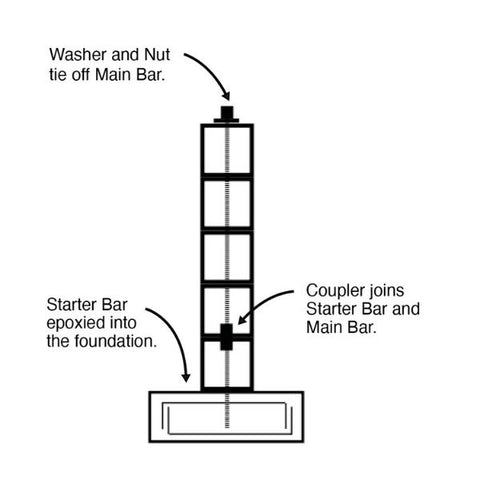

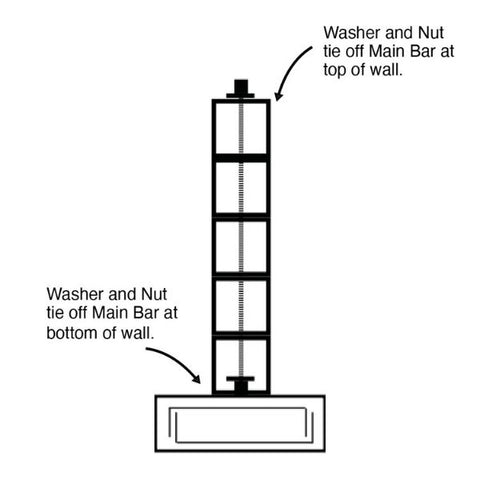

Vertical reinforcing involves a steel rod being inserted through the reinforcing ducts in the blocks and glued into the underlying concrete foundation. This combines the wall and the foundation into one super strong structure, which means the wall is able to withstand much higher loads. An alternative to tying the blocks to the concrete slab is to tie the wall together using a washer and nut at the top and bottom of the wall.

The first step of installing vertical reinforcing is for a short piece of threaded steel rod, a ‘starter bar’, to be glued into the concrete slab. A coupler is screwed onto the starter bar. The balance of the blocks are put in place. A longer piece of threaded steel rod, a ‘mainbar’, is inserted from the top of the wall and screwed into the coupler. The kit is then tied off at the top of the wall using a nut and washer.

Interbloc Fixing Kit Components and Features

“Fixing Kit” is an Envirocon term that refers to the combined components required to tall the wall together, or to the concrete foundation. There are 2 fixing kit types: standard and top and bottom.

Standard Fixing Kit

A Standard Fixing Kit consists of a starter bar epoxied into the underlying

foundation. Once the blocks have been installed, the main bar is inserted through reinforcing ducts cast into the blocks and connected to the starter bar using a coupler. Finally, the main bar is tied off at the top of the wall using a nut and washer.

Top and Bottom Fixing Kit

A Top and Bottom Fixing Kit ties the blocks in a wall together; however, it will not tie the blocks into the underlying foundation. A top and bottom fixing kit is installed post installation by inserting a main bar through the blocks with a nut and washer tying off each end.

Fixing Kit Components

| Epoxy It is most common for Fixing Kits to be epoxied into the concrete foundation - Chemset C8 Extreme or Hilti Hit-500RE are common epoxies. |  |

| Starter Bars The starter bar is a short piece of threaded reinforcing bar epoxied into the underlying foundation. |  |

| Coupler The Coupler joins the Main Bar to the Starter Bar |  |

| Main Bar The Main Bar is a length of reinforcing bar that forms the core part of the vertical reinforcing kit. The Main Bar is joined to the Starter Bar using a Coupler. |  |

| Washer and Nut The Washer and Nut tie off the top [and bottom in the case of a top and bottom fixing kit] of a wall. |  |