Boxing and In-Situ Concrete Pouring: Traditional stair construction alongside retaining walls typically involves the labor-intensive process of creating formwork (boxing) and pouring concrete on-site. This method can be expensive and time-consuming, leading to project delays and increased costs.

Timber Stairs: An alternative approach is the use of timber stairs. While timber may offer initial cost savings, it often lacks the longevity of concrete and can result in higher long-term maintenance and replacement costs.

Envirocon's innovative precast stair solution offers several advantages:

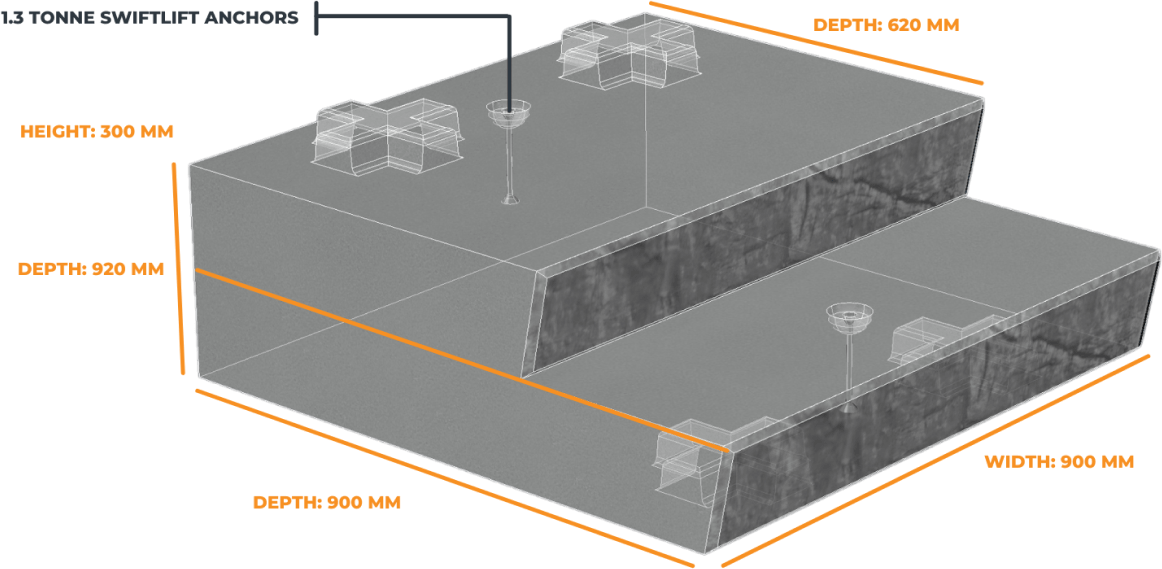

High Productivity: The precast nature of these stairs streamlines the installation process, enhancing overall productivity. Precast elements arrive ready for installation, reducing the need for on-site concrete work and associated delays.

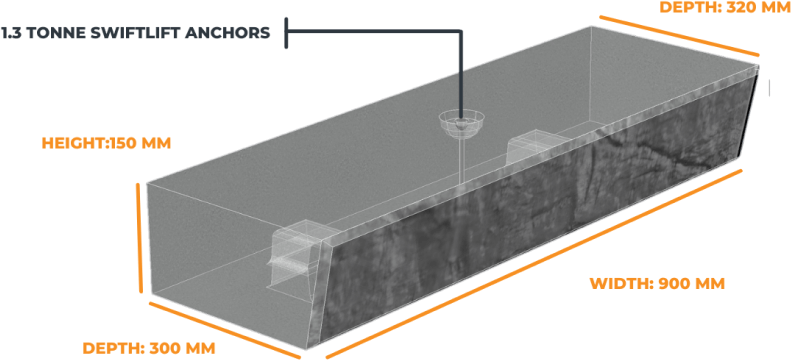

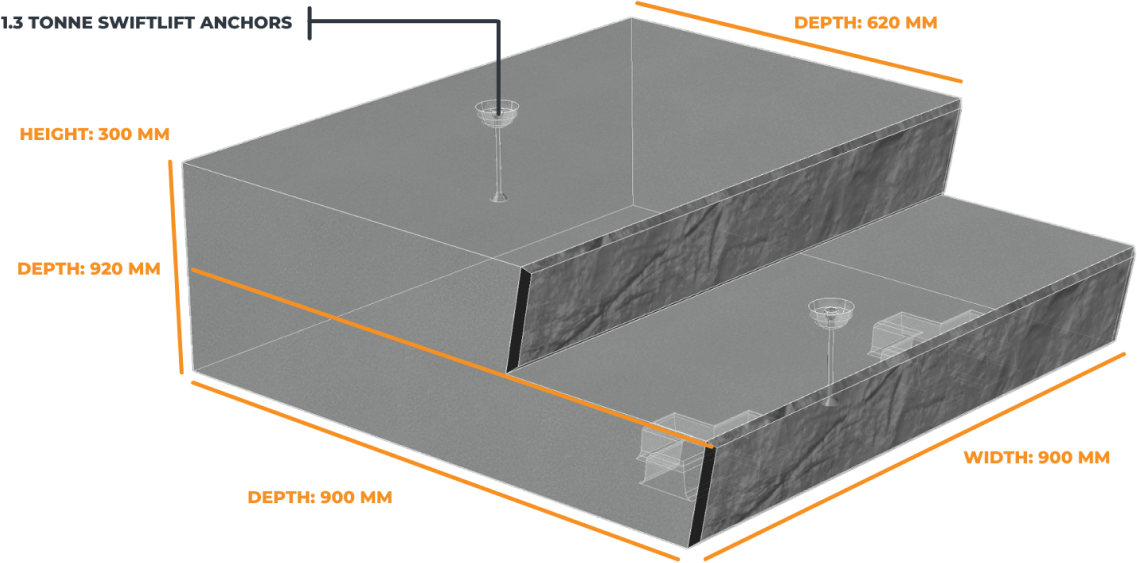

Code-Compliant Riser and Tread Dimensions: Stonebloc Precast Stairs are designed to meet code dimensions for risers and treads, ensuring safety and compliance with building regulations.

Durable Concrete Construction: These stairs are constructed from durable concrete, providing longevity and resilience in various environmental conditions. Concrete offers superior durability compared to timber, making it a cost-effective choice in the long run.

Self-Aligning and Interlocking Elements: Envirocon's precast stair elements are engineered to be self-aligning and interlocking. This design simplifies installation, reduces the risk of errors, and ensures a secure and stable stair structure.