Interbloc and timber are materials commonly used for retaining walls across various industries like civil and construction. Both solutions come with their advantages and disadvantages depending on the project. This blog will help you determine which material is best for your current or upcoming project.

Interbloc Precast Concrete Block Walls

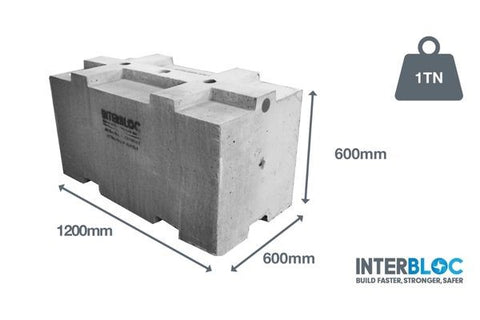

Made of wet excess concrete, Interbloc is a low carbon, zero waste precast concrete construction system - it’s CarbonSmart®. Central to the system is an interlocking, modular concrete block. Being modular, Interbloc can work across many applications (including retaining walls).

The features of the Interbloc concrete block system are:

- A shear key: This is unique to Interbloc. The interlocking shear key allows the blocks to self align and positive interlock, speeding up installation and increasing the strength of the system Interbloc blocks are always installed in a running bond pattern.

- Reinforcing ducts: To improve the capacity of the wall to take higher loads, you can add vertical reinforcing

- Certified lifting: For easy block movement and installation, at least one lifting pin is added to a block.

Timber Walls

In New Zealand, cantilevered timber walls are often viewed as the go-to for retaining walls. Not only are they used for residential retaining walls, they are also used for commercial and industrial settings, even as retention walls.

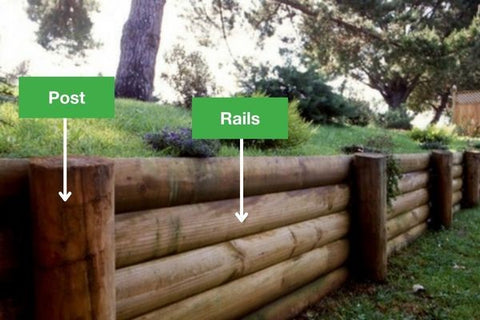

Common features of a timber wall are:

- Posts: These are the vertical pieces of timber that are concreted into the ground.

- Rails: These are the horizontal pieces of timber that retain the soil or act as retention for product

- Concrete: This is used to install the posts and make sure they don’t shift

Interbloc vs Timer: Pros and Cons

Across the board, Interbloc offers you the most advantages and least disadvantages compared to timber walls.

The areas that Interbloc wins out are

- Minimal foundations

- Fast Installation

- No pre-build inspection

- Extended durability

- Non-destructive dismantling

The Pros of Interbloc and Timber

INTERBLOC

Interbloc precast concrete blocks form a modular system full of benefits. One of the noticeable advantages of using Interbloc is the productivity gains. 2 laborers can install up to 160m2 of wall per day. And thanks to the interlocking shear key on every block, you can rearrange as you build. The shear key is what turns Interbloc into a modular system and allows for the speed of construction with the strength of concrete.

Interbloc is unique in that is holds New Zealand’s only registered Environmental Product Declaration for a precast concrete product. This EPD demonstrates that blocks have an ultra low embodied carbon footprint. The result is that Interbloc offers a sustainable alternative to timber. Combining the origin of Interbloc’s concrete with the modularity of the system makes it a perfect system to support a circular economy. If an Interbloc structure is no longer needed, you can deconstruct and sell the blocks back to us via the buyback guarantee.

Interbloc's interlocking blocks are designed for reuse; they’re very durable. Every block in the range is 600mm wide giving you a long-lasting solution. In many instances, concrete is one of the strongest building materials used in construction so be rest-assured your walls will be up for years to come. Durability can also be found with Interbloc’s code-compliant engineering and vertical reinforcement options.

When choosing Interbloc over timber, there are 2 actions you don’t need to consider. The first one being a pre-build inspection. As there are no timber poles being concrete into the ground, council consent is not required in this instance. Compared to timber, there are minimal foundations required. Interbloc structures can be built straight on a concrete foundation, or have vertical reinforcing added to create a well-engineered, strong retaining wall.

TIMBER

Timber is an acceptable solution under the NZ building code, and as such tends to be the go to for retaining in NZ. In most cases, walls under 1.5m do not need to be engineered. Over 1.5m, they need to be engineered in order to be consented by your local council.

In the general sense, adjustments are easy to be made during installation due to the ability to saw down materials as you need. Combined with the relatively light weight of the materials, construction can be completed fast (excluding concreting posts into the ground, which needs to be consented by the council).

The Cons of Interbloc & Timber

The upfront cost of installing an Interbloc wall can be greater than a timber wall. However, there is less maintenance and material replacement required compared to timber walls, so over time Interbloc will be much more cost-effective.

There are 2 main areas where Interbloc outperforms timber: longevity and installation. Even with treatment, timber walls can be suspect to rotting, warping, splitting, or termites. This leads to a building life of between 20 to 25 years (Green Future Construction). Compared to Interbloc, which will last for a minimum of 60 years, timber walls fail in comparison. Short-term maintenance for timber walls is relatively strategy forward - it’s the long-term maintenance that can be difficult.

However, timber lacks the long term durability of concrete. Even with the use of H5 treated timber, as required by the building code, the timber wall will degrade over time. We’ve all walked past a 20-year-old timber wall that is starting to sag forward with rotted rails. The solution in this instance is to replace the affected area or the entire retaining wall, costing you time and money. In contrast to this, Interbloc won’t deteriorate as it’s made from concrete - a generally stronger material than timber.

Which is more sustainable: Interbloc or Timber

INTERBLOC

Interbloc is a low carbon, zero waste construction system. Using a product stewardship, wet certified excess concrete that would’ve ended up in landfill is added to Interbloc molds. As the carbon is already allocated to the project it came from, Interbloc is low carbon. It’s New Zealand’s only precast solution that demonstrates a low carbon profile.

Low embodied carbon is not the only sustainable element of Interbloc. You also get these benefits:

- EPD Backed: With its low carbon profile, Interbloc is independently verified with an EPD from think. This will give you the reassurance that using the concrete block system is sustainable for your projects.

- Non-destructive dismantling: The modularity of Interbloc (achieved through its interlocking shear key) means you can deconstruct a wall just as easily as you can build it. Accessing utilities is easily done, and does not cause waste unlike timber

- Buyback guarantee: If you no longer need your Interbloc concrete blocks, you can sell them back to us. That way, someone else can use them and they’re not adding to New Zealand’s waste problem.

TIMBER

Like concrete, timber can be unsustainable or sustainable. In this instance, we’re talking about sustainable options with timber.

One of the main ways you’ll be able to tell if timber is sustainable is via a timber certification. In the case of New Zealand, this is the Forest Stewardship Council (FSC). This certification looks at how the use of timber and plantations affects the land, and the environment communicates and ensures forest management for future generations. When a forest is properly managed, timber can be one of the most effective carbon-storing materials (ArchiPro). By choosing timber with this certification, you can be assured that you’re sourcing a sustainable solution. In contrast to this, if this certification is not there, it could mean the timber you’re using for your wall is unsustainable.

Timber also works to reduce the planet’s carbon by storing it. In recent studies, it has been found that timber holds up to 95% of carbon even after being in a landfill for 30 years (OneFortyOne). When a forest is properly managed, timber can be one of the most effective carbon-storing materials.

Although the right timber can be sustainable, there are downsides to using it as a structural solution:

- With some fast-growing timber, there is less strength compared to an old-grown tree. Although, this can be somewhat remedied with modification and treatment. This means replacement walls (in the instance of a timber fail) are needed sooner than with concrete structures.

- If you need to deconstruct a timber structure, there is going to be waste and damaged timber. Add to this, if you need to access utilities, you need to break down the whole wall creating waste

- Wood treatment with the aim to improve longevity can harm the environment

Interbloc gives you options where timber doesn’t

Although timber does have its benefits for retaining walls, overall Interbloc is the standout performer. With its modularity, sustainability, and durability, you will have your retaining walls stand for decades.

For long-lasting retaining walls, reach out to us for a quote.